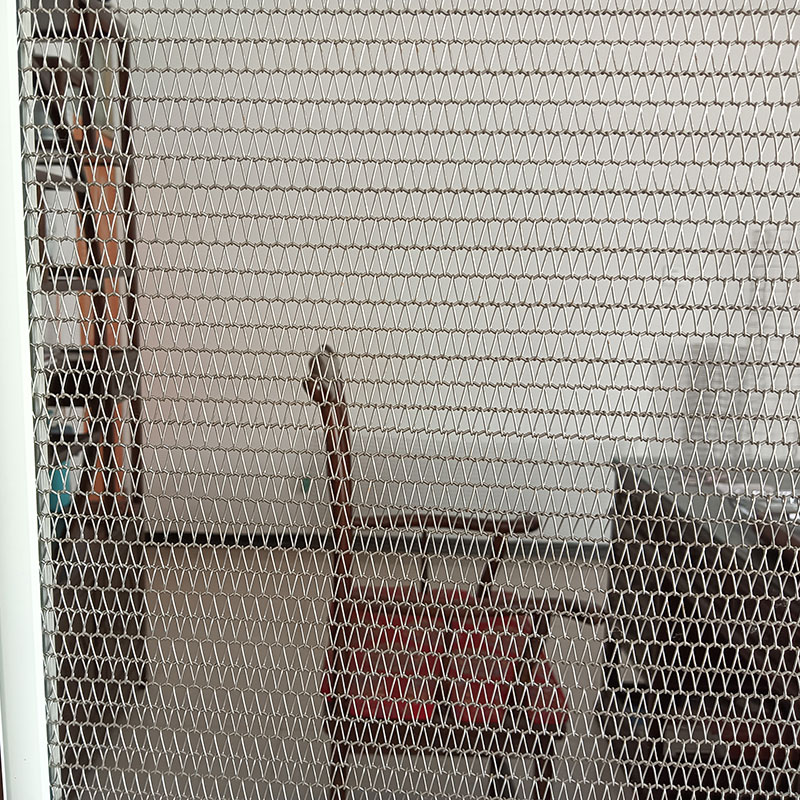

Durable and Versatile Stainless Steel Mesh for Various Applications

By:Admin

Stainless steel mesh has been playing a crucial role in various industries for decades. It provides a versatile and durable solution for filtration, sieving, and separation processes. The demand for stainless steel mesh has been increasing rapidly due to its superior quality and performance. In response to this growing demand, [Company Name] has emerged as a leading manufacturer and supplier of stainless steel mesh, providing innovative and high-quality products to meet the diverse needs of its customers.

[Company Name] has been at the forefront of the industry for over 20 years, consistently delivering top-quality stainless steel mesh products to a wide range of industries, including pharmaceuticals, food and beverage, chemical processing, and automotive. The company’s commitment to excellence and customer satisfaction has earned them a stellar reputation in the industry.

The stainless steel mesh manufactured by [Company Name] is known for its exceptional strength, corrosion resistance, and durability. It is available in various grades and specifications to meet the specific requirements of different applications. Whether it is for sieving and filtration in the pharmaceutical industry, or for architectural and design purposes, [Company Name]'s stainless steel mesh has proven to be the go-to solution for many businesses.

One of the key factors that set [Company Name] apart from its competitors is its state-of-the-art manufacturing facility. The company has invested heavily in advanced technology and equipment to ensure the highest standards of quality and precision in the production of stainless steel mesh. This allows them to maintain a leading edge in the industry and stay ahead of the competition.

In addition to its commitment to quality, [Company Name] also places a strong emphasis on sustainability and environmental responsibility. The company has implemented green initiatives and eco-friendly practices in its manufacturing processes, ensuring that its products have minimal impact on the environment. This dedication to sustainability has resonated well with its customers, who appreciate the company's efforts to operate in an environmentally conscious manner.

Furthermore, [Company Name] takes pride in its team of highly skilled and experienced professionals who are dedicated to delivering superior products and exceptional service to its customers. The company’s technical expertise and customer-centric approach have allowed them to build long-term relationships with their clients, earning their trust and loyalty.

The success of [Company Name] can also be attributed to its commitment to innovation and continuous improvement. The company constantly seeks new ways to enhance the performance and functionality of its stainless steel mesh products, staying abreast of the latest technological advancements and industry trends. This proactive approach has enabled [Company Name] to offer cutting-edge solutions that meet the evolving needs of its customers.

The future looks promising for [Company Name] as it continues to expand its presence in the global market. The company is focused on exploring new opportunities and expanding its product line to serve a wider range of industries and applications. With its unwavering dedication to excellence, sustainability, and innovation, [Company Name] is well-positioned to lead the way in the stainless steel mesh industry for years to come.

In conclusion, [Company Name] has set a high standard in the production of stainless steel mesh, earning a well-deserved reputation as a top-tier manufacturer and supplier in the industry. With its relentless pursuit of quality, innovation, and customer satisfaction, [Company Name] is poised to revolutionize the industry and solidify its position as a market leader.

Company News & Blog

High Quality Binding Wire for Sale: Types and Uses

Unleashing Innovation: A New Milestone in Binding Wire TechnologyIn an era where innovation is the driving force behind every industry, the construction sector is no exception. The demand for stronger, more durable construction materials has pushed companies to explore new technologies. One such company, {}, has made great strides in revolutionizing the binding wire industry with the introduction of their groundbreaking new product.Binding wire is an essential component in the construction industry, used for securing steel bars and reinforcing concrete structures. Traditionally, binding wire has been manufactured using conventional techniques, resulting in limitations in strength and durability. However, {} has defied these limitations with their advanced manufacturing process, delivering a binding wire that is not only stronger and more resilient but also more sustainable.The company's new binding wire is the result of extensive research and development, utilizing state-of-the-art technology to enhance its properties. By incorporating cutting-edge materials and advanced production methods, {} has succeeded in creating a binding wire that surpasses industry standards in terms of strength, durability, and corrosion resistance.One of the key features of {}'s new binding wire is its high tensile strength, which significantly exceeds that of traditional binding wire. This increased strength not only provides greater security and stability to concrete structures but also allows for more efficient and cost-effective construction processes. In addition, the advanced manufacturing process ensures that the binding wire is more durable, offering a longer service life and reducing the need for frequent replacements.Moreover, {} has placed a strong emphasis on sustainability in the manufacturing of their new binding wire. By implementing eco-friendly production methods and using recyclable materials, the company has minimized the environmental impact of their product, aligning with the global push for sustainable construction practices.The impact of {}'s innovation in binding wire technology extends beyond just the construction industry. With the growing emphasis on sustainable and resilient infrastructure, the demand for stronger and more durable construction materials has never been higher. {}'s new binding wire is set to play a pivotal role in meeting this demand, offering a solution that not only enhances the performance of concrete structures but also contributes to the overall sustainability of construction projects.The introduction of {}'s advanced binding wire is a testament to the company's commitment to innovation and excellence. As a leading manufacturer in the construction materials industry, {} has continually pushed the boundaries of technology to deliver superior products that meet the evolving needs of the market. With their new binding wire, the company has once again demonstrated their ability to lead the way in driving innovation and shaping the future of construction.In conclusion, {}'s new binding wire represents a significant milestone in the evolution of construction materials. Its superior strength, durability, and sustainability set a new standard for binding wire technology, offering a compelling solution for the construction industry's evolving needs. As the demand for stronger, more resilient infrastructure continues to rise, {}'s innovative binding wire is poised to make a lasting impact on the industry, reshaping the way concrete structures are reinforced and constructed.

All You Need to Know About Welded Wire Mesh

Title: Groundbreaking Welded Wire Mesh Innovations Revolutionize the Construction IndustryIntroduction:In recent years, the construction industry has witnessed stunning advancements in materials and technologies, leading to improvements in safety, efficiency, and overall project quality. One notable innovation that has been gaining significant attention is Welded Wire Mesh. Companies around the globe, including (remove brand name), have been introducing game-changing solutions in this field, resulting in a paradigm shift in construction practices. This article will explore the latest advancements in Welded Wire Mesh technology and highlight how they are reshaping the construction industry.The Versatility of Welded Wire Mesh:Welded Wire Mesh serves as a multi-purpose construction material, offering an array of applications in various sectors. The mesh is made up of individual wires welded together to form a strong, durable, and highly flexible structure. Its versatility allows it to be utilized in a wide range of construction projects, including residential, commercial, industrial, and infrastructure developments.Enhanced Structural Integrity:One of the key benefits of Welded Wire Mesh is its ability to enhance the structural integrity of concrete structures. By providing reinforcement, it effectively counters tensile forces, preventing cracks and reducing the risk of structural failures. Moreover, Welded Wire Mesh helps distribute load-bearing capacity across larger areas, resulting in a more stable and secure overall structure.Improved Safety Measures:With safety being a top priority in any construction project, Welded Wire Mesh has emerged as a crucial solution to reinforce concrete foundations, walls, and slabs. The mesh acts as a barrier against potential hazards such as falls, flying debris, and even natural disasters. By incorporating this technology, construction companies can ensure worker safety while delivering high-quality projects.Flexibility in Design and Installation:The flexibility offered by Welded Wire Mesh allows architects and engineers to explore innovative design possibilities while ensuring structural integrity. The mesh can be easily molded and shaped to fit complex geometries, enabling the construction of unique and visually appealing structures. Additionally, its lightweight nature makes transportation and installation hassle-free, reducing overall project time and costs.Sustainability and Environmental Benefits:Welded Wire Mesh is also making strides in promoting sustainable construction practices. By utilizing recycled materials in the manufacturing process, it reduces reliance on virgin resources, leading to a significantly lower carbon footprint. Additionally, the extended lifespan and durability of structures reinforced with Welded Wire Mesh reduce the need for frequent maintenance and repairs, further contributing to environmental sustainability.Market Adoption and Industry Collaborations:As the construction industry recognizes the inherent advantages of Welded Wire Mesh, numerous companies have joined forces to foster innovation and drive the sector forward. Various research institutions and construction conglomerates are investing in research and development initiatives focused on improving Welded Wire Mesh technologies. Collaborations between manufacturers and construction companies are paving the way for groundbreaking advancements, enabling safer, more efficient, and aesthetically pleasing projects.Conclusion:Welded Wire Mesh has emerged as a transformative force within the construction industry, offering numerous benefits ranging from improved structural integrity and safety to enhanced design possibilities and sustainable practices. As companies continue to push the boundaries of innovation, Welded Wire Mesh technology will undoubtedly play a pivotal role in shaping the future of construction. With its versatile applications and continual advancements, construction projects worldwide will see increased efficiency, durability, and overall quality in the coming years.

High-Quality Copper Wire Mesh for Various Applications

Copper Wire Mesh - A Versatile Material for Various ApplicationsCopper wire mesh is a type of versatile and durable material that is widely used in various industrial and commercial applications. It is made from high-quality copper wires that are woven together to form a strong and flexible mesh. This material offers a range of unique features and benefits, making it suitable for use in a wide range of industries, including filtration, screening, and electrical applications.The company, with its expertise in manufacturing copper wire mesh, is a leading supplier of this material to various industries across the globe. With a strong focus on quality and innovation, the company has established itself as a trusted partner for businesses looking for high-quality copper wire mesh products.One of the key features of copper wire mesh is its excellent conductivity. Copper is known for its high electrical and thermal conductivity, making it an ideal material for electrical applications. Copper wire mesh is often used in the manufacturing of electronic components, PCB boards, and electrical connectors due to its superior conductivity and reliability.In addition to its excellent conductivity, copper wire mesh also offers superior corrosion resistance. This makes it an ideal material for use in harsh and corrosive environments, such as marine applications, chemical processing plants, and oil and gas installations. The company's copper wire mesh products are manufactured to the highest standards, ensuring long-term performance and durability in challenging environments.Furthermore, copper wire mesh is also widely used for filtration and screening applications. The fine mesh structure of the material allows for efficient filtration of liquids and gases, making it suitable for use in industries such as food and beverage, pharmaceuticals, and chemical processing. The company offers a range of different mesh sizes and configurations to meet the specific filtration requirements of its customers.Another advantage of copper wire mesh is its flexibility and malleability. The material can be easily bent, shaped, and formed to fit specific design requirements, making it suitable for a wide range of custom applications. The company's in-house manufacturing capabilities allow for the production of custom-designed copper wire mesh products to meet the unique needs of its customers.Moreover, copper wire mesh is also known for its aesthetic appeal. The natural reddish-gold color of copper gives it an attractive and timeless look, making it a popular choice for architectural and decorative applications. The company offers a range of decorative copper wire mesh products that are used in interior and exterior design projects, providing both functionality and visual appeal.With a strong commitment to quality and customer satisfaction, the company ensures that its copper wire mesh products meet the highest industry standards and regulatory requirements. Through continuous research and development, the company strives to innovate and improve its product offerings to meet the evolving needs of its customers.In conclusion, copper wire mesh is a versatile and reliable material that offers a range of unique features and benefits for various industrial and commercial applications. The company, with its expertise and experience in manufacturing copper wire mesh products, is a trusted partner for businesses looking for high-quality and dependable material solutions. Whether it is for electrical, filtration, or decorative purposes, copper wire mesh is a versatile choice that delivers exceptional performance and value.

High-Quality Stainless Steel Woven Wire Mesh for Polymer Extruder Screens

Woven wire mesh is an important component in various industries, including chemical, pharmaceutical, food, and construction. It is a versatile and durable material used for filtering, separating, and shielding purposes. In this blog post, we will discuss the 2021 Woven Wire Mesh produced by Anping County Dongjie Wiremesh Products Co., Ltd., including the features, benefits, and applications of their SS304 Woven Wire Mesh.Features of SS304 Woven Wire MeshAnping County Dongjie Wiremesh Products Co., Ltd. produces high-quality SS304 Woven Wire Mesh using advanced machinery and technology. The SS304 material provides excellent corrosion resistance, strength, and durability, making it suitable for various applications.1. Excellent corrosion resistance: SS304 Woven Wire Mesh is highly resistant to corrosion, rust, and oxidation caused by water, chemicals, and pollutants. It can withstand harsh environments and extreme temperatures, making it ideal for outdoor and indoor applications.2. High strength and durability: SS304 Woven Wire Mesh is robust and durable, with a higher tensile strength than other materials. It can withstand high pressure, impact, and wear and tear, making it ideal for heavy-duty applications.3. Versatile material: SS304 Woven Wire Mesh is versatile and can be customized to meet different specifications. It comes in various mesh sizes, wire diameters, and weave patterns, making it suitable for various applications.Benefits of SS304 Woven Wire Mesh1. Optimal filtration: SS304 Woven Wire Mesh provides optimal filtration and separation of particles, liquids, and gases. It can filter out impurities, dirt, and debris from liquids and gases, making it ideal for sieving, straining, and filtering applications.2. Enhanced safety: SS304 Woven Wire Mesh provides enhanced safety and protection for workers and equipment in hazardous environments. It can shield against electromagnetic radiation, heat, and fire, making it ideal for industrial and construction applications.3. Cost-effective: SS304 Woven Wire Mesh is a cost-effective solution that reduces maintenance costs, replacement costs, and downtime. It provides long-term durability and reliability, making it a profitable investment for businesses.Applications of SS304 Woven Wire MeshSS304 Woven Wire Mesh is used in various industries, including chemical, pharmaceutical, food, and construction. It is suitable for several applications, including:1. Sieving and straining: SS304 Woven Wire Mesh is commonly used for sieving and straining applications, such as in food processing, chemical processing, and wastewater treatment.2. Filter screens: SS304 Woven Wire Mesh is used in filter screens for air, liquid, and gas separation applications, such as in filtration systems and chemical purification.3. Shielding and protection: SS304 Woven Wire Mesh is used for shielding and protecting workers and equipment from electromagnetic radiation, heat, and fire in industrial and construction applications.4. Polymer extruder screens: SS304 Woven Wire Mesh is used for polymer extruder screens, which are used in plastic extrusion processes for filtering out impurities and ensuring consistent product quality.ConclusionIn conclusion, SS304 Woven Wire Mesh is a versatile, durable, and cost-effective material used in various industries and applications. Anping County Dongjie Wiremesh Products Co., Ltd. produces high-quality SS304 Woven Wire Mesh that provides excellent corrosion resistance, strength, durability, and filtration capabilities. Its benefits include enhanced safety, optimal filtration, and cost-effectiveness, making it an ideal choice for businesses. Invest in SS304 Woven Wire Mesh from Anping County Dongjie Wiremesh Products Co., Ltd. for reliable and efficient performance.

Stainless Steel Mesh Fencing Strips in Excellent Condition for Sale

article with the following title:Innovative Stainless Steel Mesh Fencing Strips: The Latest Addition to Fence IndustryFencing is not just a physical barrier that keeps intruders out of a property. It has evolved into an integral part of the aesthetic appeal of a property. While traditional fence designs have been in use for centuries, the modern-day fence industry is constantly evolving. The latest addition to the fence industry is innovative stainless steel mesh fencing strips.The renowned brand {} has introduced a new range of stainless steel mesh fencing strips that are all set to revolutionize the fence industry. These strips are made of durable stainless steel that offers excellent resistance to harsh weather conditions, corrosion, and rust. They are designed to last for a long time without requiring frequent maintenance.One of the most remarkable features of these mesh fencing strips is its unparalleled strength and flexibility. The stainless steel mesh can be easily molded into different shapes and sizes to suit various requirements. The mesh fencing strips are available in different gauge sizes to offer different levels of protection, making them ideal for a variety of applications. From residential properties to commercial buildings, these mesh fencing strips are highly versatile and can be used to enhance the overall security and aesthetic appeal of any property.Another unique feature of these mesh fencing strips is the transparent view they provide. Unlike traditional wooden or metal fences, these strips offer a clear unobstructed view of the surroundings. This is particularly useful for commercial properties, where surveillance and visibility are of utmost importance. In addition, the open mesh design allows natural light to pass through, making it ideal for outdoor spaces that need adequate lighting.The stainless steel mesh fencing strips offered by {} are available in different colors and finishes, making it easy to match any property's architectural style and color scheme. The PVC storage containers included with the strips make transportation and storage hassle-free. Additionally, the installation of these mesh fencing strips is simple and easy.{} has established a reputation for providing the best quality fencing products in the market. The company's commitment to research and development has enabled them to stay ahead of the competition by introducing innovative fencing products that meet the ever-evolving needs of its customers. The new stainless steel mesh fencing strips are the latest addition to their already impressive product portfolio, and it is an excellent addition that is sure to meet the diverse needs of consumers.In conclusion, stainless steel mesh fencing strips are the latest addition to the fence industry, and they are setting the bar high with their remarkable features. These strips offer unparalleled strength, flexibility, visibility, and durability, making them an excellent option for both residential and commercial properties. The availability in various sizes, colors, and finishes ensures that there is an option for every property type. With these fence strips, {} has further cemented its position as a leading fencing product manufacturer worldwide.

Crimped Wire Mesh for Mining and Industrial Applications - Galvanized and Stainless Steel Options Available

for different industries and applications.Crimped Wire Mesh: A Versatile Solution for Different Industries and ApplicationsCrimped wire mesh is a type of woven wire mesh used in various industrial applications, such as mining, construction, agriculture, and filtration. It is made by weaving pre-crimped wires into a mesh pattern, which provides stability and strength to the mesh.Crimped wire mesh comes in different materials, such as stainless steel, galvanized steel, aluminum, and brass. Each material offers unique features and benefits that make it suitable for specific applications. For instance, stainless steel crimped wire mesh is corrosion-resistant and durable, making it ideal for outdoor and harsh environments. Galvanized crimped wire mesh, on the other hand, is more affordable and has better rust resistance than plain steel wire mesh.In this blog, we will discuss the various industries and applications that use crimped wire mesh, highlighting the benefits and advantages of this versatile product.Mining IndustryCrimped wire mesh is extensively used in the mining industry for screening and separating minerals and ores. The mesh is woven with high-tensile wires that can withstand the abrasive and corrosive environment of mining operations. The mesh size and wire diameter can be customized to meet specific requirements for particle size analysis and classification.Construction IndustryCrimped wire mesh is widely used in the construction industry for reinforcement purposes. It is used as a bonding material in concrete structures to provide tensile strength and stability. The mesh can also be used for decorative purposes, such as fencing, partitions, and cladding.Agriculture IndustryCrimped wire mesh is used in the agriculture industry for various purposes, including poultry fencing, livestock cages, and crop protection. The mesh provides a strong and durable barrier that keeps animals and pests out while allowing air and light to circulate.Filtration IndustryCrimped wire mesh is used in the filtration industry for liquid and gas filtration. The mesh is woven with fine wires that can capture and retain particles down to the micrometer level. The mesh can be made of different materials and configurations to meet specific filtration requirements.Other ApplicationsCrimped wire mesh is also used in other industries and applications, such as automotive, aerospace, and architecture. In the automotive industry, it is used for radiator grilles, speaker covers, and airbag screens. In the aerospace industry, it is used for engine filters, aircraft vents, and debris shields. In architecture, it is used for balustrades, screens, and shading devices.ConclusionCrimped wire mesh is a versatile and essential product that finds use in several industries and applications. It provides strength, stability, and durability to various structures and devices, making it a reliable and cost-effective solution for many applications. Choosing the right material, mesh size, and wire diameter is crucial to ensure that the crimped wire mesh meets the specific requirements and conditions of each application. Anping Huansi Wire Mesh Products Co., Ltd. offers high-quality crimped wire mesh products that meet international standards and specifications. Contact us for more information about our products and services.

Quality Binding Wire: A Resource for Securing Materials

Wire Manufacturing Company Introduces New Binding Wire for Varied Industrial ApplicationsIn a bid to address the growing demand for high-quality binding wire for various industrial applications, a leading wire manufacturing company has introduced a new and innovative product that is set to revolutionize the industry. The new binding wire, which is made from premium-grade materials and boasts of superior strength and durability, is expected to cater to the needs of diverse sectors such as construction, packaging, and manufacturing.{Company Name}, the renowned wire manufacturing company behind this breakthrough product, has a rich history of delivering top-notch wire solutions to clients across the globe. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, the company has established itself as a trusted partner for businesses seeking reliable and cost-effective wire products.The new binding wire, which is available in a range of sizes and specifications to suit different applications, is designed to offer exceptional performance and reliability. It is manufactured using advanced processes and stringent quality control measures to ensure that it meets the highest industry standards. With its superior tensile strength and resistance to corrosion, the binding wire is ideally suited for use in demanding environments and applications where durability is paramount.One of the key features of the new binding wire is its versatility, making it suitable for a wide range of industrial requirements. Whether it is for securing concrete reinforcement in construction projects, bundling and packaging materials in logistics and warehousing operations, or for various other binding applications in manufacturing and fabrication processes, this innovative wire product offers a cost-effective and efficient solution.{Company Name} has also emphasized the environmental sustainability of the new binding wire, highlighting its use of eco-friendly materials and production processes. With a commitment to reducing the environmental impact of its operations, the company has ensured that the new wire product meets stringent standards for sustainability and recyclability, aligning with the increasing focus on green practices in the industry.Furthermore, the company has invested in extensive research and development to continuously improve the performance and quality of its wire products. This dedication to innovation has resulted in the development of the new binding wire, which represents a significant advancement in the wire manufacturing sector. The company's investment in cutting-edge technology and expertise has positioned it as a leading provider of wire solutions that meet the evolving needs of modern industries.Commenting on the launch of the new binding wire, a spokesperson for {Company Name} expressed confidence in the product's ability to deliver value to customers. They stated, "We are excited to introduce our latest binding wire, which embodies our commitment to excellence and innovation. With its superior strength, durability, and versatility, we believe that this product will set new benchmarks in the industry and cater to the diverse needs of our clients. We are confident that our customers will benefit from the exceptional performance and reliability of this new wire product."The introduction of the new binding wire represents a significant milestone for {Company Name}, solidifying its position as a leading wire manufacturing company that is dedicated to meeting the evolving demands of modern industries. With its focus on quality, innovation, and sustainability, the company is poised to continue driving advancements in the wire manufacturing sector and providing innovative solutions for its global clientele.

Durable Stainless Steel Mesh - The Latest in Versatile Material Innovation

[Company Name] Introduces Innovative Stainless Steel Mesh for Various Applications[City, Date] - [Company Name], a leading manufacturer of high-quality metal products, is proud to introduce its innovative stainless steel mesh that is designed for a wide range of applications. This new product promises to deliver exceptional performance and durability, making it the go-to choice for industries such as architecture, construction, filtration, and more.With over [number of years] years of experience in the metal industry, [Company Name] has garnered a reputation for producing top-notch metal products that meet the highest industry standards. The introduction of the new stainless steel mesh is a testament to the company's commitment to innovation and quality.The stainless steel mesh offered by [Company Name] is available in a variety of sizes and configurations to cater to the specific needs of different industries. Whether it is for architectural cladding, security screens, or industrial filtration, the stainless steel mesh can be custom-made to meet the exact requirements of the project.One of the key benefits of the stainless steel mesh is its exceptional strength and durability. Made from high-quality stainless steel, the mesh is capable of withstanding harsh environmental conditions and heavy usage without compromising its performance. This makes it an ideal choice for outdoor applications where corrosion resistance is crucial.In addition to its durability, the stainless steel mesh also offers excellent versatility. It can be easily manipulated and shaped to fit different design requirements, making it a popular choice for architectural and interior design projects. Furthermore, the mesh's open area design allows for superior airflow and visibility, making it suitable for applications such as ventilation and security screens."We are thrilled to introduce our new stainless steel mesh to the market," said [Spokesperson Name], [Position] at [Company Name]. "With its exceptional strength, durability, and versatility, we believe that it will be a game-changer for a wide range of industries. Whether it is for architectural projects or industrial filtration, our stainless steel mesh is designed to deliver unparalleled performance."The introduction of the stainless steel mesh is a part of [Company Name]'s ongoing commitment to product innovation and customer satisfaction. The company prides itself on its ability to deliver custom solutions that meet the unique needs of each customer. With the new stainless steel mesh, [Company Name] aims to further solidify its position as a leading provider of metal products in the industry.As the demand for high-quality metal products continues to rise, [Company Name] is well-positioned to meet the needs of various industries with its innovative stainless steel mesh. With its exceptional strength, durability, and versatility, the stainless steel mesh is poised to become the go-to choice for architects, contractors, and manufacturers looking for reliable metal solutions.For more information about [Company Name]'s stainless steel mesh and other metal products, visit [website] or contact [phone number or email].About [Company Name]:[Company Name] is a renowned manufacturer of high-quality metal products, catering to a wide range of industries and applications. With a commitment to innovation and quality, [Company Name] has earned a reputation for delivering top-notch metal solutions that meet the highest industry standards. With a dedicated team of professionals and state-of-the-art manufacturing facilities, [Company Name] is poised to meet the evolving needs of its customers with reliable and custom metal products. For more information, visit [website] or contact [phone number or email].

Essential Guide: Understanding the Purpose and Applications of Bindling Wire

In the world of wire and cable management, the importance of a high-quality bundling wire cannot be understated. Bundling wire, also known as cable tie or zip ties, are crucial to keeping cables organized, secure and protected. With the evolution of technology, the need for reliable bundling wire has never been greater. A leading company has developed a bundling wire system that is not only dependable, but also versatile and eco-friendly.Bindling Wire, a brand of bundling wire, is a product of a leading cable management company with a history spanning over a century. The company has been a constant innovator in the field of cable management and their bundling wire is just one of the many products they offer. The bundling wire is used to secure cables and wires in place, preventing tangling, damage and interference. This simple yet effective product has made cable management a breeze in many industries such as telecommunications, electrical engineering, automotive, and construction.One of the standout features of Bindling Wire is its versatility. It comes in different sizes, lengths, and colors, and can be used for any application. The bundling wire is strong enough to secure heavy-duty cables while being gentle enough to not damage delicate wires. It is also ideal for bundling together any type of cables, wires, hoses, and pipes, which makes it a go-to solution for various industries.Another advantage of Bindling Wire is its eco-friendliness. The company is committed to reducing its carbon footprint by developing a product that is not only high-quality but also environmentally friendly. The bundling wire is made from sustainable materials and is 100% recyclable. It also has a reusable locking mechanism, which means that it can be unfastened and used again, reducing the amount of waste produced. This eco-friendly approach to cable management has won the company several awards and recognition and has made Bindling Wire a preferred choice for businesses that prioritize sustainability.Bindling Wire's success can be attributed to its commitment to quality and customer satisfaction. The company has a rigorous quality control process to ensure that every batch of bundling wire meets the highest standards. Additionally, the bundling wire undergoes strict testing to evaluate its strength, durability, and performance in the field. The company also offers excellent customer service and technical support to ensure that clients get the most out of their product.In conclusion, Bindling Wire is a testament to the fact that innovation is key to staying ahead in the field of cable management. Its versatility, eco-friendliness, and commitment to quality have made it a leader in the industry. As technology advances, the need for reliable and sustainable cable management solutions will continue to grow, and Bindling Wire is well-positioned to meet this demand.