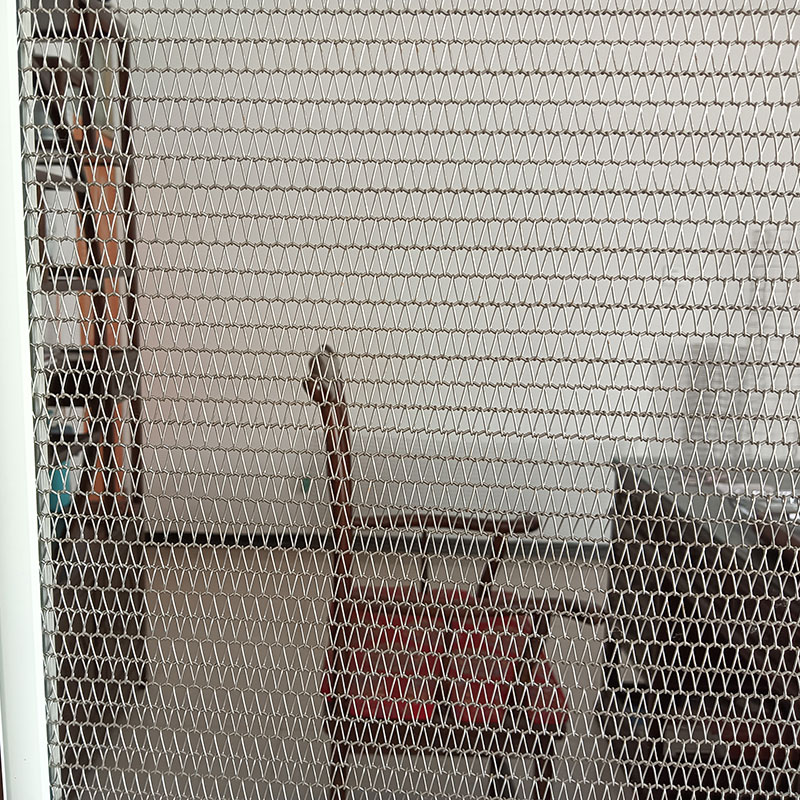

High-Quality SS304 Woven Wire Mesh for Various Applications

By:Admin

Woven wire mesh has become an integral part of numerous industrial and commercial applications due to its versatility and durability. One of the leading manufacturers of SS304 woven wire mesh has been the company {}. With decades of experience and a commitment to quality, they have established themselves as a trusted supplier in the industry.

SS304 woven wire mesh, also known as stainless steel 304 woven wire mesh, is a popular choice for various applications due to its unique properties. It is made from high-quality stainless steel grade 304, which offers excellent corrosion resistance, good strength, and a high level of hygiene. These properties make SS304 woven wire mesh suitable for use in industries such as food processing, pharmaceuticals, chemical processing, and many others.

The manufacturing process of SS304 woven wire mesh involves weaving stainless steel wires together to create a strong and durable mesh. This process is carried out with precision and attention to detail to ensure the highest quality product. The end result is a versatile material that can be used for filtration, screening, and separation of different substances.

One of the key features of SS304 woven wire mesh is its ability to withstand high temperatures and harsh environmental conditions. This makes it an ideal choice for applications that require durability and reliability. Additionally, stainless steel 304 offers resistance to corrosion and oxidation, making it suitable for use in demanding industrial settings.

The applications of SS304 woven wire mesh are diverse and varied. In the food processing industry, it is used for sieving, sorting, and filtering food products. Its hygiene properties and resistance to corrosion make it an ideal material for this purpose. In the pharmaceutical industry, SS304 woven wire mesh is used for screening and separating pharmaceutical ingredients, ensuring the quality and purity of the final products.

In the chemical processing industry, SS304 woven wire mesh is utilized for filtration and separation of different chemicals and compounds. Its resistance to corrosion and high temperatures make it a reliable choice for these applications. Additionally, this type of wire mesh is also used in architectural and decorative applications, providing both functionality and aesthetic appeal.

As a leading manufacturer of SS304 woven wire mesh, {} is committed to delivering high-quality products to meet the diverse needs of its customers. They offer a wide range of mesh sizes and specifications to cater to different requirements. With a team of experienced professionals and a state-of-the-art manufacturing facility, they ensure that their products meet the highest standards of quality and performance.

The company prides itself on its customer-centric approach, providing personalized solutions and technical support to help customers find the right product for their specific needs. With a strong focus on innovation and continuous improvement, they strive to stay at the forefront of the industry and deliver cutting-edge products that meet the evolving demands of the market.

In conclusion, SS304 woven wire mesh is a versatile and reliable material that finds extensive use in various industries. With its high-quality properties and the expertise of leading manufacturers like {}, this product continues to play a crucial role in a wide range of applications. As industries evolve and demand for high-quality materials increases, SS304 woven wire mesh is poised to remain a valuable and indispensable part of numerous manufacturing processes.

Company News & Blog

Copper Wire Mesh - Quality Exporter from China

Copper wire mesh is a type of metal mesh made from pure copper wires that are woven together to form a mesh fabric. These meshes are typically used for different purposes, such as in construction, agriculture, and industrial applications.At Chinafence, we offer high-quality copper wire meshes that are known for their durability, flexibility, and resistance to corrosion and wear. Our copper wire mesh products come in various sizes, styles, and patterns to meet different customer needs.Applications of Copper Wire MeshCopper wire meshes have numerous applications in various industries, including:1. Mining industryCopper wire meshes are used in mining to help separate and filter out different types of minerals and ores. They are also used in the electrolysis process, where copper wire meshes act as cathodes.2. Construction industryCopper wire meshes are commonly used in construction as a reinforcement material for concrete walls and floors. They are also used as decorative elements in buildings.3. Agriculture industryCopper wire meshes are used in agriculture to protect crops from insects and other pests. They are also used as bird netting to prevent birds from damaging crops.4. Industrial applicationsCopper wire meshes are used in various industrial applications, such as in the production of electronic components, filters, and screens. They are also used for shielding purposes in electronic devices.Advantages of Copper Wire MeshCopper wire meshes offer several advantages over other types of metal meshes. Some of these advantages are:1. DurabilityCopper wire meshes are highly durable and can withstand harsh weather conditions, extreme temperatures, and corrosive environments.2. FlexibilityCopper wire meshes are flexible and can be easily molded into different shapes and sizes. This makes them more versatile and adaptable to different applications.3. Resistant to corrosionCopper wire meshes are resistant to corrosion, making them ideal for use in marine environments and other corrosive environments.4. ConductivityCopper is an excellent conductor of electricity and can be used for electrical applications. Copper wire meshes are also used for RF shielding and EMI/RFI protection.ConclusionCopper wire meshes are a versatile and durable material that has various applications in different industries. At Chinafence, we offer high-quality copper wire mesh products that are suitable for different applications. If you are looking for copper wire mesh products, contact us today, and we will be happy to help you.

Explore the Benefits of Reliable Welded Wire Fences for Your Needs

[Date],[City], [State] - [Company Name], a leading provider of fencing solutions, is proud to introduce their latest product - the Welded Wire Fence. Designed to provide superior security and durability, this innovative fencing solution is set to revolutionize the industry.With the increasing demand for reliable and robust fencing options, the Welded Wire Fence offers a versatile solution for residential, commercial, and industrial applications. This new product line is set to cater to the growing needs of customers seeking reliable and long-lasting fencing solutions.The Welded Wire Fence is manufactured using high-quality materials and cutting-edge technology, making it resistant to rust, corrosion, and extreme weather conditions. The fence panels are constructed using a grid pattern of intersecting vertical and horizontal wires that are welded together at each intersection, providing added strength and stability.The welded wire mesh design offers numerous advantages over traditional fencing options. The tightly spaced wires prevent unauthorized access and ensure the safety and security of the premises. The durability of the Welded Wire Fence makes it a cost-effective solution as it requires minimal maintenance and has a longer lifespan compared to other fencing options.One of the key features of the Welded Wire Fence is its versatility. It can be seamlessly integrated into any landscape and architectural design, ensuring an aesthetically pleasing appearance without compromising on security. The fence panels are available in a variety of sizes and gauges, allowing customers to choose the best-suited option for their specific needs.The Welded Wire Fence is ideal for various applications, including residential yards, commercial properties, farms, parks, airports, and construction sites. Its versatility extends to animal enclosures, ensuring the safety of pets and livestock. The fence can also be used for creating partitions within a space or safeguarding equipment and machinery.As a company committed to quality and customer satisfaction, [Company Name] ensures that the Welded Wire Fence meets the highest industry standards. The product undergoes rigorous testing and quality control measures to guarantee its strength, durability, and performance. With their extensive experience in the fencing industry, [Company Name] is confident that the Welded Wire Fence will exceed customer expectations and provide the ultimate solution for their fencing needs.In addition to providing a durable and reliable product, [Company Name] offers comprehensive installation services. Their team of experienced professionals ensures a hassle-free and efficient installation process, ensuring that customers can start enjoying the benefits of the Welded Wire Fence as quickly as possible.To further demonstrate their commitment to customer satisfaction, [Company Name] provides excellent after-sales support. Their dedicated customer service team is available to address any queries or concerns and offer prompt assistance whenever needed. [Company Name] values its customers' feedback and continuously strives to improve their products and services based on customer insights.With the introduction of the Welded Wire Fence, [Company Name] aims to establish itself as a frontrunner in the fencing industry. Their dedication to delivering top-quality products, exceptional customer service, and innovative solutions sets them apart from competitors. By staying at the forefront of industry trends and listening to customer needs, [Company Name] is well-positioned to maintain its leadership position and continue to provide cutting-edge fencing solutions.For more information about the Welded Wire Fence or to request a quote, please visit [Company Website] or contact [Company Name] at [Contact Information].About [Company Name]:[Company Name] is a leading provider of fencing solutions, offering a wide range of products designed to meet the diverse needs of residential, commercial, and industrial customers. With a strong commitment to quality, customer satisfaction, and innovation, [Company Name] continually strives to provide the best-in-class fencing solutions in the industry.

High-Quality SS304 Woven Wire Mesh for Various Applications

SS304 Woven Wire Mesh: A High-Quality Solution for Various ApplicationsWoven wire mesh is a versatile and widely used material in various industries due to its durability, strength, and chemical resistance. One popular type of woven wire mesh is SS304, which is made of stainless steel and is known for its excellent corrosion resistance and high-temperature performance.In recent news, a leading company in the manufacturing and supply of SS304 woven wire mesh has introduced an extensive range of products to cater to the diverse needs of industrial, commercial, and residential applications. The company, with years of experience and expertise in the industry, has become a trusted provider of high-quality woven wire mesh products.The SS304 woven wire mesh offered by the company is available in various mesh sizes and wire diameters, making it suitable for a wide range of applications. Whether it is for filtration, separation, sieving, or screening, the SS304 woven wire mesh provides an effective and reliable solution. In addition, the material's resistance to rust and corrosion makes it suitable for outdoor and marine applications as well.The company takes pride in its state-of-the-art manufacturing facility, where the SS304 woven wire mesh is produced using advanced weaving techniques and quality control measures. This ensures that the final product meets the highest standards of quality and performance. Moreover, the company's team of skilled professionals is dedicated to understanding the unique requirements of each customer and providing customized solutions to meet their specific needs.One of the key advantages of SS304 woven wire mesh is its versatility. It can be used in industries such as mining, construction, agriculture, food processing, pharmaceuticals, and automotive, among others. Its strength and durability make it an ideal choice for demanding and high-stress applications. Additionally, the material's ability to withstand high temperatures and harsh environmental conditions further expands its usability across a wide spectrum of industries.The company's commitment to excellence goes beyond the quality of its products. It also places a strong emphasis on customer satisfaction and support. With a responsive and knowledgeable sales team, the company ensures prompt assistance and guidance for customers in choosing the right SS304 woven wire mesh for their specific requirements. Furthermore, the company's efficient logistics and distribution network guarantee timely and reliable delivery of products to customers across the globe.In conclusion, SS304 woven wire mesh is a superior and reliable material that offers numerous benefits across various industries. With its exceptional corrosion resistance, high-temperature performance, and robust construction, it is a preferred choice for demanding applications. The company's extensive range of SS304 woven wire mesh products, combined with its commitment to quality and customer satisfaction, positions it as a leader in the industry. Whether it is for industrial, commercial, or residential use, customers can trust the company to provide them with the highest quality SS304 woven wire mesh solutions.

High-Quality Galvanized Bar Grating for Industrial Applications

Galvanized Bar Grating: A Superior Solution for Industrial Flooring and WalkwaysIn the world of industrial construction and infrastructure, safety and durability are of utmost importance. That's why companies around the globe rely on high-quality galvanized bar grating to provide secure flooring and walkway solutions. With its exceptional strength and corrosion-resistant properties, galvanized bar grating is an essential component in numerous industries, including manufacturing, petrochemical, and transportation.At the forefront of this industry is {Company Name}, a leading manufacturer and supplier of galvanized bar grating. With a strong commitment to quality and innovation, {Company Name} has established itself as a trusted provider of industrial safety solutions.{Company Name} has been in the business of manufacturing galvanized bar grating for over 20 years. Their grating products are designed to meet the highest industry standards and undergo rigorous testing to ensure superior performance in demanding environments. With a state-of-the-art manufacturing facility and a team of experienced engineers, {Company Name} has the capability to produce a wide range of grating products to meet the unique needs of their customers.One of the key advantages of galvanized bar grating is its exceptional corrosion resistance. The process of galvanization involves coating the grating with a layer of zinc, which provides protection against rust and corrosion. This makes galvanized bar grating an ideal choice for outdoor applications and industrial settings where exposure to harsh elements is a concern.In addition to its corrosion resistance, galvanized bar grating is known for its high strength-to-weight ratio, making it a cost-effective and durable solution for industrial flooring and walkways. Its open design also allows for the easy passage of light, air, and moisture, making it an ideal choice for drainage and ventilation systems.{Company Name} offers a wide range of galvanized bar grating products to meet the diverse needs of their customers. This includes welded bar grating, swage-locked grating, and pressure-locked grating, available in a variety of materials, including carbon steel, stainless steel, and aluminum. These products can be customized to specific sizes, shapes, and load requirements, ensuring that customers receive a solution tailored to their unique application.Furthermore, {Company Name} is committed to sustainable practices, and their galvanized bar grating products are 100% recyclable, making them an environmentally friendly choice for industrial flooring and walkway solutions.The applications for galvanized bar grating are vast and varied. It is commonly used for industrial flooring, catwalks, mezzanines, stair treads, and platform systems. The durability and safety features of galvanized bar grating also make it an ideal choice for use in oil and gas facilities, chemical plants, power plants, and transportation infrastructure.{Company Name} takes pride in its ability to provide high-quality galvanized bar grating products that meet the stringent requirements of their customers. Their dedicated team of experts works closely with clients to understand their specific needs and deliver tailored solutions that exceed expectations. With a strong emphasis on customer satisfaction and a proven track record of success, {Company Name} has earned a solid reputation in the industry.As the demand for durable and reliable industrial flooring and walkway solutions continues to grow, the importance of galvanized bar grating cannot be overstated. {Company Name} is well-positioned to meet this demand, thanks to their unwavering commitment to quality, innovation, and customer satisfaction.In conclusion, galvanized bar grating is a superior solution for industrial flooring and walkways, offering exceptional strength, corrosion resistance, and versatility. {Company Name} is a trusted provider of galvanized bar grating, known for its commitment to quality and customer satisfaction. With their extensive experience and expertise, {Company Name} is well-equipped to meet the diverse needs of their customers and deliver tailored solutions that exceed expectations.

High-Quality Galvanized Bar Grating: A Complete Guide

Galvanized Bar Grating Provides Durable and Versatile Solutions for Industrial and Commercial ApplicationsGalvanized bar grating has become a popular choice for industrial and commercial applications due to its durability, versatility, and cost-effectiveness. This type of grating is commonly used in platforms, walkways, stair treads, and other flooring applications because of its ability to withstand heavy loads and harsh environments.One of the leading suppliers of galvanized bar grating is [Company Name], a renowned manufacturer with a strong reputation for providing high-quality products and exceptional customer service. With over [number] years of experience in the industry, [Company Name] has established itself as a trusted source for galvanized bar grating and other steel products.The galvanization process involves applying a protective zinc coating to steel to prevent rust and corrosion, making it an ideal choice for outdoor and indoor applications. This coating also provides a non-slip surface, making galvanized bar grating a safe and reliable option for areas with high foot traffic.In addition to its longevity and corrosion resistance, galvanized bar grating offers impressive strength-to-weight ratios, making it suitable for a wide range of industrial and commercial applications. The open design of the grating allows for drainage and ventilation, making it an ideal choice for areas where moisture and airflow are important considerations.[Company Name] offers a comprehensive range of galvanized bar grating products, including welded steel bar grating, pressure-locked grating, swage-locked grating, and riveted grating. These products are available in various sizes, materials, and configurations to meet the specific needs of different industries and applications.The team at [Company Name] is committed to providing customized solutions to their customers, working closely with them to understand their requirements and offer expert advice on the best grating products for their projects. With state-of-the-art manufacturing facilities and a team of skilled professionals, [Company Name] has the capability to produce galvanized bar grating that meets the highest quality standards and exceeds customer expectations.In addition to their extensive product range, [Company Name] also offers value-added services such as custom fabrication, cutting, and finishing to ensure that their customers receive ready-to-install grating solutions that meet their exact specifications. This commitment to quality and customer satisfaction has earned [Company Name] a loyal customer base and a strong reputation in the industry.The applications for galvanized bar grating are diverse, ranging from industrial facilities, manufacturing plants, and chemical processing plants to commercial buildings, transportation infrastructure, and architectural projects. With its exceptional strength, durability, and corrosion resistance, galvanized bar grating is a versatile solution for a wide range of environments and requirements.In conclusion, galvanized bar grating is a valuable investment for industrial and commercial applications, offering a combination of strength, durability, and cost-effectiveness. With [Company Name] as a trusted supplier, customers can have confidence in the quality and reliability of their galvanized bar grating solutions. Whether it's for a small-scale project or a large-scale industrial application, [Company Name] has the expertise and resources to deliver the right grating products to meet their customers' needs.

What is Perforated Metal and how it is Made: Materials and Techniques Used

Perforated metal sheet is a highly versatile and useful material that is used in a variety of applications. It is a type of sheet metal that has been punched or stamped, creating a pattern of holes, slots, or decorative shapes. This pattern can be customized to suit the needs of the specific application, and can range from simple geometric shapes to intricate designs.Materials used to manufacture perforated metal sheets include stainless steel, cold rolled steel, galvanized steel, brass, aluminum, tinplate, copper, Monel, Inconel, titanium, plastic, and more. This wide range of materials makes it possible to create perforated metal sheets that are suitable for many different applications, from industrial and architectural to decorative and artistic.One of the main benefits of perforated metal sheet is its ability to allow for the passage of air, light, and sound. This makes it an ideal material for use in ventilation systems, acoustic panels, lighting fixtures, and signage. Perforated metal sheets can reduce noise levels in industrial settings, improve air flow in HVAC systems, and enhance the aesthetic appeal of architectural features.Another benefit of perforated metal sheet is its strength and durability. It can withstand high levels of stress and strain, making it suitable for use in applications that require resistance to impact and abrasion. Perforated metal sheets are also resistant to corrosion, which makes them ideal for use in outdoor or marine applications.The versatility of perforated metal sheet is what makes it such a useful material. It can be used in a wide range of industries, from construction and architecture to manufacturing and automotive. It is used in the production of screens, filters, guards, trays, baskets, and more. It is also used in the creation of decorative features such as wall panels, room dividers, and art installations.In conclusion, perforated metal sheet is a highly versatile and useful material that is used in many different applications. Its ability to allow for the passage of air, light, and sound, combined with its strength and durability, make it an ideal choice for a wide range of industries. If you need a material that is strong, durable, and customizable, consider using perforated metal sheet for your next project.

Durable and Versatile Copper Wire Mesh for a Variety of Applications

Copper Wire Mesh Improves Performance in Industrial ApplicationsCopper wire mesh has long been used in industrial applications for its conductivity, corrosion resistance, and strength. It is a versatile material that can be woven into various mesh sizes and patterns to meet the specific needs of different industries. In recent years, the demand for high-quality copper wire mesh has been on the rise, as industries seek to improve the performance and reliability of their products and processes.{Company Name} is a leading manufacturer of copper wire mesh, offering a wide range of products that are designed to meet the needs of a diverse range of industries. The company has been in the business for over 20 years and has built a strong reputation for delivering high-quality, reliable products that meet the strictest industry standards.One of the key advantages of {Company Name}'s copper wire mesh is its superior conductivity. Copper is one of the most conductive metals, making it an ideal material for applications that require high levels of electrical conductivity. The company's copper wire mesh is used in a wide range of electrical and electronic applications, including RF shielding, EMI/RFI shielding, and grounding applications.In addition to its conductivity, copper wire mesh offers excellent corrosion resistance, making it suitable for use in harsh industrial environments. This makes it a popular choice for applications in the aerospace, automotive, and marine industries, where components are exposed to moisture, salt, and other corrosive elements. {Company Name} offers a range of copper wire mesh products that are specifically designed to withstand these challenging conditions, ensuring the long-term reliability and performance of their customers' products.Another key benefit of {Company Name}'s copper wire mesh is its strength and durability. The company's products are manufactured using high-quality materials and advanced weaving techniques, resulting in a mesh that is strong, durable, and able to withstand high temperatures and mechanical stress. This makes it suitable for a wide range of industrial applications, including filtration, sieving, and separation processes. {Company Name} offers a range of mesh sizes and patterns to meet the specific requirements of different applications, ensuring that their customers can find the right solution for their needs.With the increasing demand for high-quality copper wire mesh, {Company Name} has invested in state-of-the-art manufacturing facilities and quality control processes to ensure that their products meet the highest standards of quality and performance. The company's team of experienced engineers and technicians are committed to delivering innovative solutions that meet the evolving needs of their customers, working closely with them to develop customized products that meet their specific requirements.In addition to its commitment to quality, {Company Name} is dedicated to providing exceptional customer service and support. The company's team works closely with their customers to understand their needs and provide them with the best possible solutions, offering technical advice, product recommendations, and after-sales support to ensure that their customers can achieve the best possible results.As the demand for high-quality copper wire mesh continues to grow, {Company Name} is well-positioned to meet the needs of a wide range of industries, offering innovative solutions that improve the performance and reliability of their products and processes. With its commitment to quality, innovation, and customer service, {Company Name} is a trusted partner for companies looking for high-quality copper wire mesh solutions.

Rewrite: "Discover the Advantages of Copper Wire Mesh for Various Applications

Copper Wire Mesh Revolutionizes the Industrial Sector: A New Product by [Company Name][City, Date] - [Company Name], a leading innovator in the field of wire mesh manufacturing, is excited to announce the launch of its latest breakthrough product - Copper Wire Mesh. Designed to revolutionize the industrial sector, this innovative solution promises to enhance performance, durability, and overall quality across various applications.Copper, known for its exceptional electrical conductivity, thermal resistance, and antimicrobial properties, has long been a preferred material in numerous industries. Building upon copper's inherent advantages, [Company Name] has leveraged its expertise to develop a high-quality Copper Wire Mesh that meets the evolving demands of modern industrial applications."This new product is a game changer in the wire mesh industry," said [Company Name]'s spokesperson. "We have meticulously engineered every aspect of Copper Wire Mesh to deliver superior performance, durability, and reliability, ensuring that our customers can achieve their goals with increased efficiency."An essential characteristic of Copper Wire Mesh is its exceptional electrical conductivity. Copper's high electrical conductivity ensures minimal energy loss along transmission lines, making it an ideal material for electric and electronic applications. The Copper Wire Mesh, incorporating this property, enhances the efficiency of electrical systems, reducing energy consumption and optimizing performance.Furthermore, Copper Wire Mesh exhibits excellent thermal resistance, allowing it to withstand extreme temperatures without compromising its structural integrity. This makes it a valuable asset in applications such as heat exchangers, filtration systems, and industrial ovens, where reliable performance under high heat conditions is crucial.Aside from its electrical and thermal properties, Copper Wire Mesh also possesses antimicrobial properties, making it a suitable choice for medical facilities, laboratories, and food processing industries that prioritize hygiene and contamination prevention. Copper has been scientifically proven to actively kill bacteria, viruses, and other harmful microorganisms on its surface, offering a natural defense against potential pathogens.[Company Name]'s commitment to quality is evident in its meticulous manufacturing process. The Copper Wire Mesh is created using the latest technology and adheres to rigorous quality control measures, ensuring consistency and reliability in every roll produced. Moreover, the company's team of experts continuously tests the Copper Wire Mesh to meet industry standards and specifications, providing customers with peace of mind and confidence in their purchase."Our focus has always been on delivering innovative solutions that empower our customers to succeed," said [Company Name]'s spokesperson. "We've put our expertise and resources into developing Copper Wire Mesh, and we are confident that it will have a significant impact across various industrial sectors."The applications of Copper Wire Mesh are vast, ranging from electrical components and circuits to filtration systems and architectural designs. Its versatility, combined with its exceptional properties, makes it an ideal material for industries such as telecommunications, power generation, aerospace, automotive, and more.As [Company Name] introduces Copper Wire Mesh into the market, they anticipate a surge in demand from industries looking to enhance their processes, improve reliability, and mitigate potential risks associated with traditional wire mesh materials.About [Company Name]:[Company Name] is a renowned manufacturer and supplier of wire mesh products. With decades of experience, the company has built a strong reputation for delivering high-quality solutions across a range of industries. From standard wire mesh to custom-designed solutions, [Company Name] is committed to innovation, integrity, and customer satisfaction.To learn more about Copper Wire Mesh and other products offered by [Company Name], visit their official website at [Website URL].Contact:[Company Name][Address][Phone Number][Email Address]

60 ft Brown Chain Link Fence with Gates, Posts and Top Rails for Sale in Kingston

: The Versatile and Durable Fencing Option for Your Home If you're looking for a versatile and durable fencing option for your home, look no further than the chain link fence. This type of fence is a popular choice for both residential and commercial properties, and for good reason. It's affordable, low-maintenance, and can be customized to fit your specific needs. In this blog post, we'll take a closer look at the benefits of chain link fences and why they might be the right choice for you.Durability and StrengthWhen it comes to fencing materials, chain link is one of the strongest and most durable options available. The fence is made of galvanized steel, which has been coated with zinc to prevent rust and corrosion. This means that the fence can withstand harsh weather conditions and will last for many years if properly installed and maintained.Low-MaintenanceOne of the biggest advantages of chain link fences is that they require very little maintenance. Unlike wood fences that need to be regularly painted or stained, chain link fences can simply be hosed down to keep them looking clean. Additionally, the fence's metal material makes it impervious to insects, rot, and decay, so you don't have to worry about replacing individual boards or sections of the fence.Customizable OptionsAnother benefit of chain link fences is that they can be customized to fit your specific needs. For example, if you have pets and want to keep them from escaping, you can install a taller fence with smaller gaps between the metal links. You can also add privacy slats or decorative panels for a more attractive look. Additionally, chain link gates can be designed to match the style of the fence itself and come in a variety of sizes to accommodate larger vehicles like RVs or boats.AffordabilityWhen compared to other fencing options like wood or vinyl, chain link fences are significantly more affordable. This makes them a great choice for homeowners who want to install a fence on a budget. Additionally, the low-maintenance nature of the fence means that you won't have to spend a lot of money on upkeep over time.ConclusionOverall, chain link fences are a versatile, durable, and affordable option for homeowners who want to add security and privacy to their property. Whether you're looking to keep pets or children in, or unwanted visitors out, a chain link fence is a great choice. With many customizable options available, you can create a fence that not only serves its practical purpose but also looks great on your property. If you're interested in installing a fence, consider using chain link for a reliable and effective solution.

Durable Steel Grating: A Must-Have for High-Traffic Areas

Steel Grating is a leading manufacturer of high-quality steel grating products. With a strong focus on quality, innovation, and customer satisfaction, Steel Grating has become a trusted name in the industry. The company's commitment to excellence has led to a wide range of products that are used in various applications, including industrial, commercial, and residential environments.Steel Grating offers a comprehensive range of steel grating products, including standard grating panels, stair treads, and custom-designed grating systems. The company's products are designed to meet the highest standards of performance and durability, making them ideal for use in demanding applications. Steel Grating's dedication to quality is evident in the materials used in their products, as well as the precision engineering and manufacturing processes that are employed.One of the key factors that sets Steel Grating apart from its competitors is its commitment to innovation. The company is constantly striving to develop new and improved products that offer enhanced performance and durability. This dedication to innovation has led to the development of a range of patented technologies that are used in Steel Grating's products. These technologies have allowed the company to stay ahead of the curve and continue to provide its customers with cutting-edge solutions.In addition to its commitment to quality and innovation, Steel Grating is also dedicated to providing superior customer service. The company takes pride in its ability to work closely with customers to understand their specific needs and provide customized solutions that meet their requirements. This customer-centric approach has earned Steel Grating a reputation for reliability and dependability, making it a preferred choice for customers around the world.Steel Grating's products are used in a wide range of applications, including industrial flooring, mezzanines, stair treads, and trench covers. The company's grating systems are designed to provide exceptional strength and durability, making them ideal for use in demanding environments. Whether it's a heavy-duty industrial facility or a commercial building, Steel Grating has the products and expertise to meet the unique requirements of any project.With a strong focus on quality, innovation, and customer satisfaction, Steel Grating has established itself as a leader in the steel grating industry. The company's dedication to excellence, coupled with its commitment to providing superior customer service, has earned it a strong reputation in the market. As the company continues to grow and expand its product offerings, it is poised to remain at the forefront of the industry for years to come.In conclusion, Steel Grating is a company that is committed to providing high-quality steel grating products that meet the highest standards of performance and durability. With a focus on innovation and customer satisfaction, the company has established itself as a trusted name in the industry. Whether it's for an industrial, commercial, or residential application, customers can rely on Steel Grating to deliver superior products and exceptional service.