Top Considerations When Choosing a Reliable Wire Mesh Fence

By:Admin

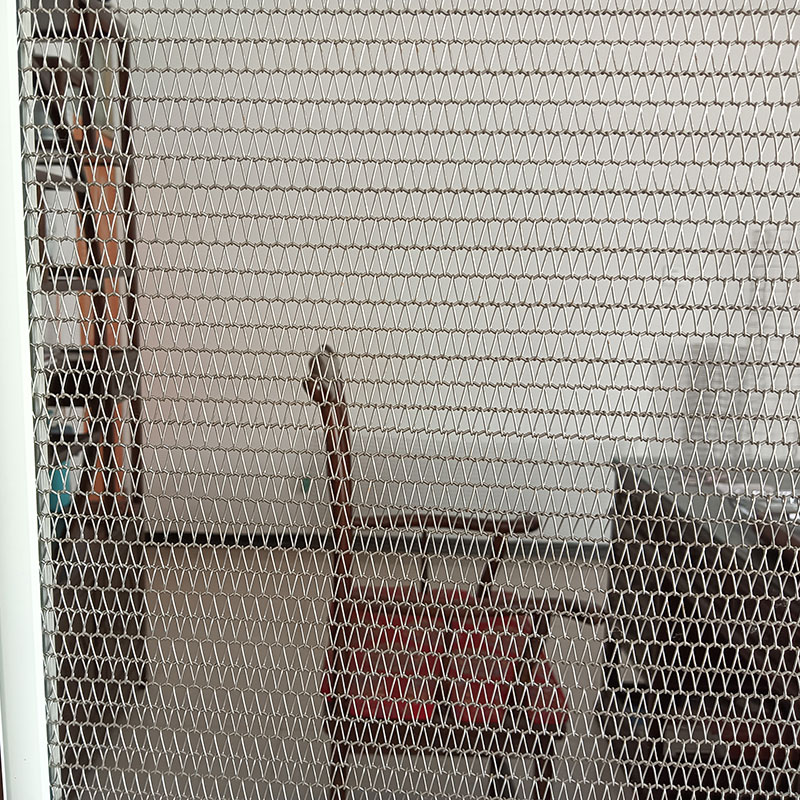

Wire Mesh Fence: The Ultimate Solution for Modern Construction Needs

The construction industry has witnessed rapid growth in recent years, thanks to numerous technological advancements and innovative building techniques. Among these advancements, the use of wire mesh fence has revolutionized how construction projects are done, thereby boosting efficiency and improving the aesthetics of structures. In this article, we explore the benefits of using wire mesh fence in modern construction.

Wire mesh fence is a versatile fencing material that is made of galvanized or PVC-coated steel wire, woven into a mesh pattern. This type of fence has gained popularity in construction projects as it is durable, economical, and easy to install. The following are the benefits of using a wire mesh fence in construction:

Improved Safety

Safety is a critical aspect of any construction project, and the use of wire mesh fence improves overall site safety. Wire mesh fence creates a secure boundary that prevents unauthorized access to the construction site. The fence also protects workers and the general public from any potential hazards on site, such as falling debris, sharp objects, or hazardous machines. Additionally, wire mesh fence serves as an effective barrier against animals or pests that may pose a danger to the workers on-site.

Durability and Longevity

Wire mesh fence is a robust fencing material that is designed to withstand harsh weather conditions and withstand the test of time. The fence is usually galvanized or coated with PVC. Galvanization involves dipping the steel wire in molten zinc, which creates a protective layer that prevents rust and corrosion. PVC coating, on the other hand, involves covering the wire mesh with a layer of plastic, making it more resistant to impact and abrasions. This makes wire mesh fence more durable than traditional fencing materials such as wood, chain-link and barbed wire.

Easy Installation

The installation of wire mesh fence is quick and straightforward, thanks to its lightweight design and simple construction. The fence requires minimal tools and materials, making it an ideal choice for small to medium construction projects. The wire mesh fence comes in different sizes and shapes, making it possible to adapt to the specific needs of each site. The installation of the fence only requires two people, thereby reducing labor costs and time spent on installation.

Environmentally Friendly

Wire mesh fence is an environmentally friendly fencing material that is made from recycled steel wire. This makes it a sustainable option for construction projects, as it helps to reduce carbon emissions and environmental impact. Additionally, because of its durability, wire mesh fence is reusable and can be moved from one site to another, further reducing construction waste.

Versatility

Wire mesh fence is available in a wide range of sizes, colors, and styles, making it a versatile fencing option for construction projects. Contractors can choose from a variety of mesh sizes depending on the application, with smaller mesh sizes providing more security and larger mesh sizes providing more visibility. Additionally, wire mesh fence can be painted to match the specific color scheme of the construction site, enhancing the overall aesthetic appeal of the project.

Conclusion

In conclusion, wire mesh fence is a versatile and cost-effective fencing solution that offers numerous benefits to modern construction projects. It is durable, easy to install, environmentally friendly, and provides enhanced safety and security to the construction site. The use of wire mesh fence significantly improves the efficiency of construction projects, thereby reducing construction time and costs. With its numerous benefits, it's easy to see why wire mesh fence has become the fencing material of choice for many in the construction industry.

Company News & Blog

Explore a Wide Range of High-Quality Twin Loop Wire Binding Machines & Systems

If binding wire is a part of your business, then you should know that selecting the right binding machine can make all the difference. However, with the wide variety of options available, choosing the right one can be overwhelming. To help you make an informed choice, we’ve put together this comprehensive guide to selecting the right wire binding machines.Wire binding, also known as Twin Loop Binding or Double Loop Binding, is a popular binding method that utilises a double loop wire that is inserted through the punched holes in the pages to hold them together. Wire binding is a versatile binding style, as it is available in a wide variety of sizes and can handle both small and large documents.When choosing a wire binding machine, there are several factors to consider, including size, capacity, and durability.Size: The size of your wire binding machine should match your specific needs. Smaller machines are designed for home offices or small businesses with low volume binding requirements. However, if you plan on binding a large number of documents, then you will need a larger machine.Capacity: The capacity of your wire binding machine determines how many sheets of paper it can bind at one time. The higher the capacity, the more sheets it can handle. If you frequently bind large documents, then you should choose a machine with a high capacity to save time.Durability: The durability of your wire binding machine is another important consideration. You want a machine that is built to last and can handle the wear and tear of daily use. A sturdy machine can save you money in the long run as it won't need to be replaced as often.In addition to these factors, you should also consider the pitch and wire size for your wire binding machine.Pitch: Pitch refers to the distance between the holes punched in the pages. A 3:1 pitch has three holes per inch, while a 2:1 pitch has two holes per inch. If you’re binding a large document, a 2:1 pitch may be the best option since it can handle more sheets.Wire Size: The wire size you choose will depend on the number of pages you plan to bind. A larger wire size can handle more pages, but it may not be the best option if you don't need to bind large documents.When it comes to choosing a wire binding machine, there are several great options available to you.To begin with, you can choose from a range of manual and electric wire binding machines. Manual machines are more affordable and are perfect for low-volume binding. On the other hand, electric machines are an excellent choice for high volume binding as they can bind documents quickly and efficiently.Another option is the modular system. With a modular system, you can build your binding machine to suit your needs. You can choose from a range of modules, including punching modules, closing modules, and binding modules, to create a customised machine that meets your specific needs.Overall, the wire binding machine you choose will depend on your specific needs and requirements. Whether you opt for a manual or electric machine, size, capacity, and durability should be the primary considerations. Be sure to choose a machine that is built to last and that can handle your daily work requirements.In conclusion, selecting the right wire binding machine is critical if you want to efficiently and effectively bind your documents. There is a wide variety of options available, and choosing the right one can make all the difference. With the information in this guide, you can make an informed decision and choose a wire binding machine that best suits your needs.

Steel Bar Grating: Strong and Versatile for Various Applications

Steel Bar Grating: Revolutionizing Industrial Flooring SolutionsIn the world of industrial flooring solutions, one product has revolutionized safety, durability, and versatility - steel bar grating. Known for its exceptional strength, reliability, and cost-effectiveness, steel bar grating has become the go-to option for industries across the globe. With its impressive load-bearing capacity and longevity, it provides a secure and efficient flooring solution for a wide range of applications.Steel bar grating, also referred to as steel grating, is a series of parallel, flat, and bearing bars that are joined by perpendicular crossbars. This unique design offers an open grid construction, allowing the passage of light, air, and moisture, while providing excellent traction for enhanced safety. The bars are generally manufactured with various shapes, such as plain, serrated, or I-bar profiles, to cater to diverse industrial requirements.One prominent steel bar grating manufacturer leading the industry is {}. With years of expertise in steel fabrication, they have gained recognition for their high-quality products and commitment to customer satisfaction. Their steel bar gratings are known for their exceptional strength, durability, and resistance to corrosion, making them ideal for a multitude of industrial applications.The versatility of steel bar grating makes it a popular choice for countless industries. Industries such as oil and gas, mining, construction, transportation, and manufacturing extensively utilize steel bar gratings for their flooring, stair treads, platform, and walkway applications. The open grid design of steel bar grating enables efficient drainage, which is vital in industries where liquids or debris are present. Additionally, the design also prevents the accumulation of dirt, reducing maintenance costs and enhancing overall cleanliness.Safety is a paramount concern in any industry, and steel bar grating excels in providing a secure working environment. The raised surface of the bars offers improved traction, reducing the risk of slips, trips, and falls. Moreover, the serrated or I-bar profiles enhance grip, making it suitable for applications where workers handle hazardous materials or operate heavy machinery. With its high load-bearing capacity, steel bar grating ensures stability and prevents structural failures, supporting the safety of workers and preventing accidents.Durability is another key factor that sets steel bar grating apart. Constructed with high-quality steel, it can withstand heavy loads, impact, and extreme weather conditions. This longevity reduces the need for frequent replacements, resulting in cost savings for businesses in the long run. Furthermore, with advancements in galvanization techniques, steel bar grating can be hot-dip galvanized or coated with protective materials to enhance its resistance to corrosion, extending its lifespan even further.When it comes to installation, steel bar grating offers ease and efficiency. Its modular design allows for easy customization and adaptability to various floor layouts and dimensions. Additionally, it can be fabricated in standard panels, enabling swift installation without the need for complex cutting or welding procedures. This not only saves time but also reduces labor costs, making it a preferred choice for many industries.As industries continue to prioritize safety, durability, and cost-effectiveness in their flooring solutions, steel bar grating remains at the forefront. With its outstanding features and remarkable benefits, it has become an indispensable component for industries worldwide. Leading manufacturers like {} continue to innovate and provide top-notch steel bar gratings, ensuring that industrial facilities can achieve optimal safety and efficiency.In conclusion, steel bar grating's unrivaled strength, durability, and versatility have transformed industrial flooring solutions. With its ability to provide safety, exceptional load-bearing capacity, and ease of installation, steel bar grating has become an indispensable choice for industries across the globe. As technology and manufacturing techniques advance, steel bar grating will continue to play a vital role in ensuring the safety and efficiency of industrial operations.

How to Build a Durable and Effective Gabion Retaining Wall

Title: Innovative and Sustainable Gabion Retaining Wall Solution Revolutionizes Urban LandscapingIntroduction:In recent years, urban landscapes have seen a surge in construction and development. With limited space available, developers and architects are faced with the challenge of creating sustainable and visually appealing structures. Gabion Retaining Wall (GRW) has emerged as a groundbreaking solution, perfectly blending functionality with aesthetics. This article will delve into the concept of GRW and highlight its specific benefits, highlighting its potential to revolutionize urban landscaping.Understanding Gabion Retaining Walls:Gabion Retaining Walls are unique, modular structures that incorporate wire baskets, known as gabions, filled with rocks or other appropriate materials. These gabions are then stacked together to form sturdy and versatile retaining walls. What sets them apart from conventional retaining walls is their adaptability, allowing them to easily fit and conform to an array of landscapes and terrains.In addition to being visually appealing, GRWs provide excellent erosion control and prevent soil displacement. These qualities make them an ideal solution for retaining walls in various applications, including highways, river banks, parks, and private residences. Furthermore, GRWs can be customized to incorporate planting shelves, further enhancing their aesthetic appeal and contributing to greener urban environments.Benefits of Gabion Retaining Walls:1. Environmental Sustainability: GRWs prioritize sustainability by utilizing natural materials such as rocks and recycled fillers, minimizing carbon footprints associated with traditional construction methods. By employing locally sourced materials, GRWs significantly reduce transportation and extraction costs.2. Cost-Effectiveness: Compared to other retaining wall solutions, GRWs are relatively cost-effective. The use of locally sourced materials and simplified installation processes translates into reduced labor and machinery expenses, providing developers and contractors with an economical choice.3. Versatility and Adaptability: Whether used to support steep slopes, erosion control, or defining landscape boundaries, GRWs are highly versatile. They can be seamlessly integrated into any architectural design, providing optimal support with their structural integrity.4. Structural Durability: The galvanized steel wire baskets that create the gabions are highly resistant to corrosion, UV rays, and extreme weather conditions. This durability ensures a long-lasting structure and minimal maintenance requirements, making GRWs a favorable long-term investment.Application Examples and Success Stories:GRWs have been successfully implemented in numerous projects across the globe, providing remarkable solutions for various urban landscapes:1. Urban Revitalization Project: In a major city's waterfront revitalization project, GRWs were utilized as part of an extensive beautification program. The gabions, filled with colorful stones, elevated the landscape's aesthetics while addressing concerns related to soil erosion and stability.2. Highway Infrastructure: GRWs have proven to be invaluable for highway infrastructure projects. By efficiently preventing soil erosion, securing embankments, and stabilizing slopes, GRWs contribute to ensuring safe and reliable transportation routes within urban areas.3. Residential Solutions: GRWs have gained popularity among homeowners seeking a sustainable and visually appealing alternative to traditional retaining walls. These structures can be seamlessly incorporated into private gardens and landscapes, adding an aesthetic touch while providing necessary functionality.Conclusion:Gabion Retaining Walls offer a groundbreaking and sustainable solution for urban landscaping challenges. With their adaptability, durability, and aesthetic appeal, GRWs have successfully transformed numerous projects worldwide. By prioritizing environmental sustainability and providing cost-effective alternatives, GRWs are poised to continue revolutionizing urban landscapes and leave a lasting impact on construction practices in the years to come.

Gabion Baskets Used to Build Access Track Along Train Station

and Access Track to improve search engine optimization.Gabion Retaining Walls and Access TracksGabion retaining walls have become popular due to their cost-effective and environmentally friendly benefits. The use of gabion baskets in retaining walls is now prevalent in many construction projects.One example of how gabion baskets can be used is in the construction of access tracks. Access tracks are essential in industrial developments as they provide a safe and efficient way for vehicles to move around. Access tracks can also be used in train stations to provide a route for maintenance vehicles to access the track.Gabion baskets are ideal for constructing retaining walls for access tracks as they are strong and durable. The nature of gabion baskets also makes them perfect for retaining the site boundary along the length of an access road.The use of gabion retaining walls in access tracks has many benefits. The walls are made up of wire mesh cages filled with rocks and other materials. The holes in the baskets allow water to flow through, reducing pressure on the wall and preventing erosion.Gabion retaining walls are also eco-friendly as they use natural materials with a low carbon footprint. The materials can be sourced locally, reducing transportation costs and emissions.Another benefit of gabion retaining walls is their flexibility. They can be contoured to fit the shape of the land, providing a smooth and safe access track. The flexibility of the baskets also allows for expansion and contraction with temperature changes, preventing cracking and damage.The installation of gabion retaining walls for access tracks is also straightforward. The baskets are easy to transport and can be assembled on site, reducing construction times and costs.In conclusion, the use of gabion retaining walls in access tracks is an excellent choice for industrial developments and train stations. The benefits of gabion retaining walls, including their strength, durability, and eco-friendliness, make them an ideal choice for constructing retaining walls for access tracks. Their flexibility and ease of installation also make them a popular choice for many construction projects.

Looking for High-Quality Wire Mesh? Contact Us Today for Fast and Reliable Service!

Wire Mesh – The Ideal Solution for a Wide Range of ApplicationsWire mesh is a versatile material that has a wide range of applications across various industries, including construction, manufacturing, agriculture, and more. It is a woven or welded material that is made up of multiple interlocking wires, with openings of various sizes and shapes between them. Wire mesh is available in different materials, including stainless steel, aluminum, brass, and copper, and can be customized to suit specific requirements.Martin Hale T/A Vulcan 502250 is one of the leading suppliers of wire mesh in the UK. With over two decades of experience in the industry, the company has built a reputation for quality, reliability, and excellent customer service. Based in Cambridgeshire, Vulcan 502250 has a wide range of wire mesh products available, including welded mesh, woven wire mesh, stainless steel mesh, and more.Welded MeshWelded mesh is a type of wire mesh that is made up of welded steel wire, with uniformly spaced rectangular or square gaps. The wires are welded together at each intersection, creating a strong, durable material that is ideal for fencing, animal enclosures, machine guards, and more. Welded mesh can be customized to suit specific sizes and shapes, and can also be coated with PVC for additional protection against rust and corrosion.Woven Wire MeshWoven wire mesh is made up of woven wires that are crisscrossed and interlocked at each intersection. This type of wire mesh is available in a wide range of gauges and opening sizes, making it suitable for a variety of applications, including filtration, sieving, and decorative purposes. Woven wire mesh is also available in different materials, including stainless steel, brass, and aluminum.Stainless Steel MeshStainless steel mesh is an excellent choice for applications that require high levels of strength, durability, and corrosion resistance. This type of wire mesh is made up of stainless steel wires that are woven or welded together, creating a strong and reliable material that can withstand harsh environments. Stainless steel mesh is commonly used in the food and beverage industry, as well as in medical applications, where hygiene and cleanliness are essential.Customized Wire MeshAt Martin Hale T/A Vulcan 502250, we understand that every customer has unique requirements when it comes to wire mesh. That's why we offer customized wire mesh solutions that are tailored to meet your specific needs. Whether you require a specific mesh size, shape, or material, our team of experts can work with you to develop a customized solution that meets your exact requirements.In addition to our wide range of wire mesh products, we also offer a range of related services, including cutting, shaping, and welding. Our team of experts has the knowledge and experience to provide you with the highest quality wire mesh products and services, ensuring that your project is completed to the highest standards.In conclusion, wire mesh is a versatile and durable material that is essential in many industries. Whether you require welded mesh for fencing, woven wire mesh for filtration, or stainless steel mesh for medical applications, Martin Hale T/A Vulcan 502250 has the expertise and knowledge to provide you with the right solution for your needs. Contact us today to discuss your wire mesh needs and to receive a quote.

Exploring the Versatility and Durability of Steel Grating in the Industry

Title: Innovative Steel Grating Solution Improves Safety and Efficiency in Industrial SettingsIntroduction:In the ever-evolving industrial landscape, safety and efficiency remain paramount concerns. One company, renowned for its cutting-edge solutions, continues to revolutionize the field by introducing an innovative steel grating system. By incorporating state-of-the-art technology and a commitment to excellence, this company has significantly enhanced workplace safety and operational efficiency in various industries. This news article will explore the benefis of this groundbreaking steel grating system and its potential implications for industrial settings.Body:1. The Importance of Steel Grating in Industrial Settings (approx. 150 words)Steel grating plays a critical role in safeguarding industrial personnel and enhancing operational effectiveness. It serves as a versatile and durable flooring solution that enables the passage of light, air, and liquid while providing additional support. In industries such as manufacturing, oil and gas, construction, and mining, steel grating is utilized extensively across walkways, platforms, staircases, and drainage systems.2. Introduction of the Innovative Steel Grating System (approx. 200 words)The company's latest offering combines cutting-edge technology with highly engineered steel grating to offer an unparalleled solution to several industry challenges. With a focus on enhancing safety, the grating system integrates robust anti-slip properties, ensuring workers' protection against slips and falls even in harsh environments.Furthermore, this new steel grating's advanced design allows for easy installation and maintenance, minimizing downtime and maximizing productivity. Its durable and corrosion-resistant properties ensure longevity and reduce the need for frequent replacements, thus leading to significant cost savings for companies.3. Enhanced Safety Features (approx. 150 words)The innovative steel grating system incorporates advanced safety features to meet the demanding requirements of industrial environments. Its anti-slip surface provides superior traction, even during wet or oily conditions, effectively reducing the risk of accidents and injuries. Additionally, the grating design promotes proper drainage and prevents pooling of liquids, minimizing the potential for slips while improving overall cleanliness.4. Improved Efficiency and Optimum Performance (approx. 200 words)Apart from its safety benefits, the cutting-edge grating system enhances operational efficiency across various industrial applications. The open design facilitates improved ventilation and light transmission, ensuring a more comfortable working environment. By allowing the passage of air and light, this steel grating system reduces the accumulation of dust and helps maintain optimal working conditions.Furthermore, the grating's structural integrity and load-bearing capacity make it ideal for heavy-duty usage. Its ability to withstand heavy loads and impacts increases the lifespan of the flooring solution, reducing downtime for repairs or replacements.5. Versatility and Customization Options (approx. 100 words)Recognizing that each industry has unique requirements, the company offers a range of customization options for its innovative steel grating system. Clients can choose from various sizes, shapes, and patterns, allowing them to tailor the grating to specific project needs. This versatility ensures seamless integration into existing structures, enhancing overall efficiency and aesthetics.Conclusion:The introduction of this innovative steel grating system presents a game-changer for industries seeking enhanced safety measures and operational efficiency. With its advanced features, including anti-slip properties, durability, and versatility, this steel grating solution is poised to revolutionize industrial settings. As the company continues to push boundaries, it serves as a shining example of industry-leading innovation in the pursuit of a safer and more productive working environment.

Overview of Electric Fusion Welded Wire Mesh for Construction Projects

: The Ultimate Guide for Industrial UseWelded wire mesh is a prevalent material used in industries of all kinds. It is a type of prefabricated joined grid made of parallel longitudinal wires with accurate spacing welded to cross wires at the required spacing. This mesh is commonly used in construction, agriculture, transportation, and security applications. In this blog post, we will delve into the uses, benefits, and types of welded wire mesh.Uses of Welded Wire Mesh1. Construction and BuildingWelded wire mesh is an essential component in the construction industry. It is used to reinforce concrete structures such as floors, walls, and slabs, providing added strength and stability. It is also used in the installation of plumbing and electrical systems.2. AgricultureThe farming industry uses welded wire mesh for various applications, such as fencing, animal enclosures, crop protection, and trellises. The mesh provides a durable and long-lasting solution for farm needs.3. TransportationWelded wire mesh is used in the manufacturing of vehicles, trailers, and cargo carriers. The mesh is used to reinforce and provide stability to the vehicle's structure, making it safer during transit.4. SecurityThe use of welded wire mesh as a security measure is widespread. It is often used in high-security areas such as prisons, military bases, and airports. The mesh provides a sturdy barrier that can deter intruders and prevent unauthorized entry.Benefits of Welded Wire Mesh1. DurabilityWelded wire mesh is known for its durability and resilience. It can withstand harsh weather conditions and heavy usage, making it a long-lasting and cost-effective solution.2. FlexibilityWelded wire mesh is available in various sizes, shapes, and configurations. This makes it a popular choice for a range of applications, allowing for customization to fit specific needs.3. Easy to InstallWelded wire mesh is easy to install and requires minimal preparation. The mesh can be cut to the desired size and shape, making it easy to work with on the job site.4. Cost-EffectiveWelded wire mesh is an affordable alternative to traditional materials such as wood or metal. It is low-maintenance, long-lasting, and does not require frequent replacements, making it a cost-effective solution.Types of Welded Wire Mesh1. Stainless Steel Welded Wire MeshStainless steel welded wire mesh is widely used in corrosive environments where rust and corrosion are a concern. It is popular in the food industry, construction, and water treatment plants.2. Galvanized Welded Wire MeshGalvanized welded wire mesh is coated with zinc to prevent rust and corrosion. It is widely used in agriculture, construction, and fencing applications.3. PVC-Coated Welded Wire MeshPVC-coated welded wire mesh is used in applications where a decorative or colorful mesh is desired. It is often used in gardening and landscaping applications.ConclusionWelded wire mesh is a versatile and cost-effective solution for a variety of industrial applications. Its durability, flexibility, and easy installation make it an excellent choice for construction, agriculture, transportation, and security needs. Whether you require stainless steel, galvanized, or PVC-coated welded wire mesh, there is an option to suit your specific requirements. Choose welded wire mesh for your next industrial project and enjoy the benefits of this reliable and durable material.

New Aluminum Fencing Option: Chain Link Fence with Privacy Slats

Title: Advanced Security Solution Provider Introduces Innovative Fencing TechnologyIntroduction:In the ever-evolving landscape of security solutions, one company is revolutionizing the industry with their pioneering approach. Combining cutting-edge technology with their expertise in perimeter security, this renowned provider is introducing an advanced fencing system that ensures maximum protection. By leveraging their state-of-the-art technology, this company is setting new standards in security infrastructure.Innovative Fencing Solution:With a deep understanding of the evolving security challenges faced by various industries, this market-leading company has developed an innovative fencing solution. This next-generation system, known as an 'Advanced Security Barrier' -- designed to replace conventional chain link fences -- incorporates advanced materials and intelligent features to provide unparalleled protection.Enhanced Durability:The company's new fencing system is constructed using high-grade materials that are highly resistant to wear and tear, weather conditions, and tampering. With durability at the forefront, this advanced security barrier surpasses traditional chain link fences in strength and longevity, providing clients with long-term protection and peace of mind.Intelligent Sensors and Alert Systems:To further fortify its security capabilities, this advanced fencing system incorporates intelligent sensors and alert systems. These state-of-the-art sensors are strategically placed throughout the fence and detect any unauthorized intrusion or tampering. Once triggered, real-time alerts are immediately sent to the security personnel, enabling them to swiftly respond to potential threats.Integration with Integrated Security Systems:One of the standout features of this advanced system is its seamless integration with existing or newly implemented integrated security systems. By synchronizing with other security components like surveillance cameras, access control systems, and intrusion detection systems, this advanced fencing solution creates a comprehensive and cohesive security infrastructure. Such integration enables swift and effective response measures in the event of a security breach, ensuring the safety of both people and assets on-site.Customization Options:Understanding that different industries and organizations have unique security requirements, this company offers a wide range of customization options, tailoring the advanced fencing system to meet specific needs. Clients have the flexibility to choose various fence heights, materials, and colors to match their surroundings, while maintaining the highest level of security.Applications across Industries:The versatility of this innovative fencing solution makes it suitable for a diverse range of industries. From critical infrastructure facilities, government premises, and military installations to educational institutions, commercial establishments, and residential communities, the advanced security barrier provides reliable protection in any setting.Unmatched Expertise and Reliability:Backed by years of experience and a commitment to excellence, this company prides itself on providing unmatched expertise and reliability. With a team of highly skilled professionals, they work closely with clients to understand their unique security challenges, offering tailored solutions that meet their specific requirements. From the initial design phase to installation and post-sales support, this dedicated team ensures a seamless experience for their clients.Conclusion:With its revolutionary advanced fencing solution, this renowned security provider is changing the landscape of perimeter security. By combining cutting-edge technology, durable materials, and intelligent features, they have created a system that offers unmatched protection, seamlessly integrated with existing security infrastructure. With their commitment to excellence and acclaimed reliability, this company continues to meet the evolving security needs of various industries, setting new standards in advanced security solutions.

High-Quality Galvanized and Iron Wires: Suppliers and Manufacturers in China

Galvanized Iron Wire: A Reliable and Durable Choice for a Wide Range of ApplicationsGalvanized iron wire is a popular choice for a variety of applications due to its strength, durability, and resistance to corrosion. In fact, it is one of the most commonly used types of wire in the construction industry, as well as in agriculture, manufacturing, and many other fields. Let's take a closer look at what makes galvanized iron wire such a reliable and versatile material.What is Galvanized Iron Wire?Galvanized iron wire is made by coating a base wire, typically made of steel or iron, with a layer of zinc through the process of hot-dip galvanizing. This coating helps to protect the wire from corrosion and other types of wear and tear, making it a durable choice for a wide range of uses.Galvanized iron wire can come in a variety of thicknesses and gauges, depending on the intended application. Thicker wires are generally stronger and more durable, while thinner wires can be more flexible and easier to work with.Benefits of Galvanized Iron WireThere are many benefits to using galvanized iron wire over other types of wire. Here are just a few:1. Corrosion resistance: The zinc coating on galvanized iron wire provides excellent corrosion resistance, making it ideal for use in harsh environments where other types of wire may quickly deteriorate.2. Durability: Galvanized iron wire is incredibly strong and durable, making it ideal for heavy-duty applications such as construction and agriculture.3. Versatility: Galvanized iron wire can be used for a wide range of applications, including fencing, wiring, and binding.4. Low cost: Galvanized iron wire is generally less expensive than other types of wire, making it a cost-effective choice for many applications.Uses of Galvanized Iron WireGalvanized iron wire is used in a wide range of applications across many industries. Here are just a few examples:1. Fencing: Galvanized iron wire is often used to create strong and durable fencing for agricultural and industrial applications.2. Binding: Galvanized iron wire is commonly used to bind materials such as hay bales and building materials together.3. Wiring: Galvanized iron wire is often used for electrical wiring and other types of wiring in construction.4. Construction: Galvanized iron wire is commonly used in construction applications such as reinforcing concrete, tying rebar, and bracing structures.ConclusionGalvanized iron wire is a versatile and durable choice for a wide range of applications. Its resistance to corrosion, strength, and low cost make it a popular choice for construction, agriculture, and many other industries. Whether you need to create strong and durable fencing, bind materials together, or wire a building, galvanized iron wire is an excellent choice.

Professional Twin Loop Wire Binding Machines & Systems for Efficient Binding

Wire Binding: A Comprehensive Solution for Binding NeedsWire binding is an efficient and cost-effective way to bind important documents together. It is used widely in various industries like education, government, legal, and corporate offices, among others. Wire binding offers several benefits, including durability, versatility, and professionalism in appearance. Whether you are looking to bind a few sheets of paper or thick reports, wire binding is an ideal solution for your binding needs.Introduction(Company name) is a leading provider of high-quality binding machines, supplies, and accessories, and has been serving customers for over a decade now. The company takes pride in offering a wide range of wire binding machines and systems to meet the unique needs of different customers. Our products are made of high-quality materials, ensuring durability and longevity, and designed with the latest technology to meet evolving binding requirements.Wire Binding MachinesOur wire binding machines come in various sizes, capacities, and functionalities, allowing customers to choose the right machine for their specific needs. The machines are designed to be compact, easy to use, and efficient, ensuring that you can bind documents quickly and accurately.Our wire binding machines range from manual, electric, and automated, and customers can choose from desktop machines, free-standing, or portable machines. Our machines come with a wide range of wire punching and binding capacities, depending on the number of pages you need to bind.Wire Binding SuppliesWe offer a wide selection of wire binding supplies suitable for binding different sizes and types of documents. Our wire binding supply range includes twin loop wire, spines, binding covers, and backs. Our wire spines come in a wide range of sizes and colors, allowing you to choose the right spine for your documents. The spines range from 1/4" to 1½" in diameter, allowing you to bind up to 300 pages.Our wire binding covers and backs come in different sizes, from letter to legal, and colors, including clear, black, white, and blue. Our covers and backs are made of high-quality materials, ensuring that your documents look professional, clean, and organized. We also offer thermal binding covers, ring binders, and comb bindings for customers who prefer other types of binding solutions.Advantages of Wire BindingWire binding has several benefits that make it a popular choice for binding documents. Some of the advantages of wire binding include:Durability: Wire binding provides excellent durability and longevity to bound documents. Unlike other binding methods like stapling, wire binding holds up well over time, ensuring that documents remain secure and intact.Versatility: Wire binding is versatile and can be used for a wide range of document types, including proposals, reports, presentations, and manuals.Professional appearance: Wire binding provides a professional appearance to bound documents and gives them a corporate feel that makes an excellent first impression.Ease of use: Wire binding is easy to use, and binding documents with wire spines is a quick and straightforward process. Wire binding machines are designed to be user-friendly, making them perfect for beginners or professionals alike.Cost-effective: Wire binding is a cost-effective binding solution for small and large businesses alike, as it requires less maintenance and setup costs than other binding methods.ConclusionWire binding is a comprehensive solution for all your binding needs, and (company name), with its wide selection of wire binding machines, supplies, and accessories, is the perfect place to fulfill your binding needs. Our products are made of high-quality materials, ensuring durability, longevity, and a professional appearance to all your bound documents. Whether you are looking to bind reports, presentations, manuals, or proposals, our wire binding solutions are bound to meet your specific needs.