Essential Guide to Binding Wire: Uses, Types, and Benefits

By:Admin

Binding Wire Company, a leading provider of construction materials, has recently launched a new and innovative product aimed at enhancing the construction industry. The new product, binding wire, has been designed to meet the growing demands of construction projects by providing a reliable and efficient solution for securing and reinforcing building materials.

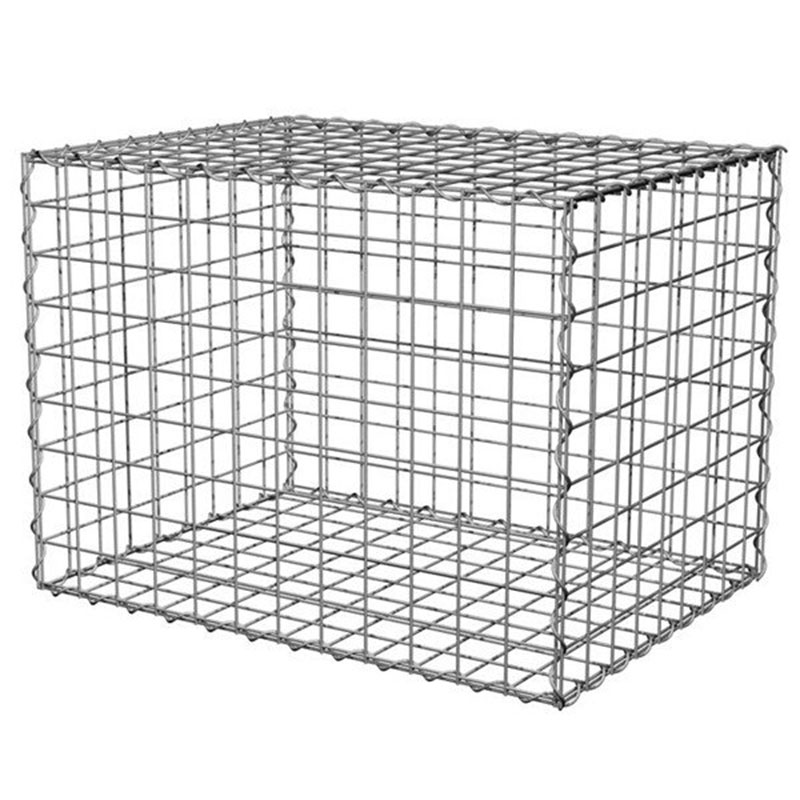

Binding wire, also known as bale wire or soft wire, is a type of wire used in the construction industry to securely bind materials such as steel bars or mesh. It is typically made from high quality steel and is available in various gauges and thickness to accommodate different construction needs. The product is commonly utilized to reinforce concrete structures, secure rebar, and tie together building materials, making it an essential component in the construction of buildings, bridges, roads, and other infrastructure.

The introduction of the binding wire by Binding Wire Company has been met with great enthusiasm from industry professionals and construction companies. The product has been hailed for its exceptional quality, durability and reliability, and has quickly gained a reputation as a superior solution for securing and reinforcing building materials. Moreover, the binding wire is manufactured in compliance with industry standards and is rigorously tested to ensure its performance and longevity, giving customers peace of mind knowing they are using a product they can trust.

One of the key benefits of the binding wire is its flexibility and ease of use, which makes it suitable for a wide range of construction applications. Whether it is securing reinforcing bars, bundling materials, or providing additional support for construction projects, the binding wire offers a versatile solution that can be easily adapted to suit various construction needs. This versatility and adaptability make it an ideal choice for construction companies and contractors looking for a reliable and cost-effective solution to their binding needs.

In addition to its functionality, the binding wire is also available in a variety of finishes and coatings, including galvanized and PVC-coated options. These finishes provide added protection against rust and corrosion, making the binding wire suitable for use in diverse environments and weather conditions. This ensures that the wire maintains its integrity and performance over time, enhancing the longevity of construction projects and reducing the need for costly maintenance and repairs.

The introduction of the binding wire is a testament to Binding Wire Company's commitment to providing innovative and high-quality solutions to the construction industry. With a focus on quality, reliability and customer satisfaction, the company has established itself as a trusted partner for construction professionals, offering a comprehensive range of construction materials and accessories that meet the highest standards of performance and durability.

The binding wire is just one of many products offered by Binding Wire Company, which also includes a wide range of construction materials such as steel bars, mesh, fencing, and other accessories. With a global presence and a strong reputation for excellence, the company is dedicated to helping construction professionals achieve their project goals by delivering top-notch products and exceptional customer service.

As the construction industry continues to evolve and demand for reliable and efficient building materials grows, the introduction of the binding wire by Binding Wire Company is a clear demonstration of the company's commitment to innovation and excellence. With a focus on quality, functionality, and customer satisfaction, the binding wire is poised to make a significant impact in the construction industry, providing a superior solution for securing and reinforcing building materials.

Company News & Blog

Durable and Secure Wire Mesh Fence for Your Property

The use of wire mesh fences has been gaining popularity in recent years due to its durability and versatility in various applications. One company that has been at the forefront of providing high-quality wire mesh fence solutions is {Company Name}. Established in 1995, {Company Name} has been a leading manufacturer and supplier of wire mesh products, offering a wide range of options for different industrial, commercial, and residential needs.The company takes pride in its state-of-the-art manufacturing facilities, which are equipped with advanced machinery and technology to ensure the production of top-notch wire mesh products. With a team of experienced and skilled professionals, {Company Name} is dedicated to providing innovative and customized solutions to meet the unique requirements of its clients.One of the key products offered by {Company Name} is its wire mesh fence, which is designed to provide security, safety, and privacy for various applications. The wire mesh fence is constructed using high-quality materials, such as galvanized steel, stainless steel, or PVC-coated wire, to ensure long-lasting performance in different environmental conditions. It is available in a variety of designs, including welded mesh panels, chain link fences, and expanded metal fences, catering to different aesthetic and functional needs.The wire mesh fence from {Company Name} is widely used in industrial settings, such as factories, warehouses, and construction sites, where security and safety are paramount. Its robust construction and tamper-resistant design make it an ideal solution for perimeter protection, preventing unauthorized access and ensuring the safety of personnel and assets.In addition to industrial applications, the wire mesh fence is also commonly used in commercial and residential settings. It offers a cost-effective and low-maintenance solution for boundary demarcation, securing commercial properties, public areas, and residential compounds. Its transparent design allows for visibility and airflow while providing an effective barrier against intruders and unwanted wildlife.Furthermore, {Company Name} offers customization options for its wire mesh fence, allowing clients to choose the size, shape, color, and additional features to suit their specific needs. Whether it's for crowd control at events, animal enclosures at zoos, or landscaping in outdoor spaces, the wire mesh fence from {Company Name} is designed to deliver reliable performance and aesthetic appeal.The commitment to quality and customer satisfaction is evident in {Company Name}'s dedication to complying with international standards and certifications, ensuring that its wire mesh products meet the highest industry benchmarks. The company also emphasizes sustainability and environmental responsibility in its manufacturing processes, utilizing eco-friendly materials and practices to minimize its carbon footprint.With a strong focus on customer service and support, {Company Name} provides comprehensive assistance to its clients, from initial consulting and design to installation and after-sales services. Its team of experts is readily available to address inquiries, offer technical guidance, and provide efficient solutions to ensure a seamless experience for customers.In conclusion, the wire mesh fence from {Company Name} continues to be a preferred choice for a wide range of applications, thanks to its high-quality construction, customizable options, and comprehensive support services. As the demand for reliable perimeter security and enclosure solutions grows, {Company Name} stands poised to meet the needs of its clients with its innovative and durable wire mesh fence products.

Copper Wire Mesh - Quality Exporter from China

Copper wire mesh is a type of metal mesh made from pure copper wires that are woven together to form a mesh fabric. These meshes are typically used for different purposes, such as in construction, agriculture, and industrial applications.At Chinafence, we offer high-quality copper wire meshes that are known for their durability, flexibility, and resistance to corrosion and wear. Our copper wire mesh products come in various sizes, styles, and patterns to meet different customer needs.Applications of Copper Wire MeshCopper wire meshes have numerous applications in various industries, including:1. Mining industryCopper wire meshes are used in mining to help separate and filter out different types of minerals and ores. They are also used in the electrolysis process, where copper wire meshes act as cathodes.2. Construction industryCopper wire meshes are commonly used in construction as a reinforcement material for concrete walls and floors. They are also used as decorative elements in buildings.3. Agriculture industryCopper wire meshes are used in agriculture to protect crops from insects and other pests. They are also used as bird netting to prevent birds from damaging crops.4. Industrial applicationsCopper wire meshes are used in various industrial applications, such as in the production of electronic components, filters, and screens. They are also used for shielding purposes in electronic devices.Advantages of Copper Wire MeshCopper wire meshes offer several advantages over other types of metal meshes. Some of these advantages are:1. DurabilityCopper wire meshes are highly durable and can withstand harsh weather conditions, extreme temperatures, and corrosive environments.2. FlexibilityCopper wire meshes are flexible and can be easily molded into different shapes and sizes. This makes them more versatile and adaptable to different applications.3. Resistant to corrosionCopper wire meshes are resistant to corrosion, making them ideal for use in marine environments and other corrosive environments.4. ConductivityCopper is an excellent conductor of electricity and can be used for electrical applications. Copper wire meshes are also used for RF shielding and EMI/RFI protection.ConclusionCopper wire meshes are a versatile and durable material that has various applications in different industries. At Chinafence, we offer high-quality copper wire mesh products that are suitable for different applications. If you are looking for copper wire mesh products, contact us today, and we will be happy to help you.

HEXMESH Grating: The Ultimate Solution for Concrete Framing

for Concrete, Concrete Framing, McNICHOLS, and Hexagonal Grid.When it comes to creating durable and reliable concrete structures, framing is key. Without proper reinforcement, concrete can be prone to cracking, blistering, and other types of damage. That's where galvanized bar grating for concrete framing comes in. And in particular, McNICHOLS Clinched HEXMESHGrating has proven itself to be a top choice among builders and construction professionals.What sets HEXMESHGrating apart is its unique hexagonal grid structure. Made with rectangular bars that are clinched together, this grating provides exceptional support and reinforcement for concrete structures. It helps to evenly distribute weight and pressure, reducing the likelihood of cracking or other types of damage. And because it's available in a variety of sizes and configurations, it can be tailored to meet the specific needs of any project or application.One of the biggest advantages of McNICHOLS Clinched HEXMESHGrating is its versatility. It can be used in a wide range of concrete applications, from walls and floors to refractory installations. And because it's made with galvanized steel, it's highly resistant to rust, corrosion, and other forms of weathering. This makes it ideal for use in outdoor or industrial settings, where durability is paramount.Beyond its practical benefits, HEXMESHGrating also offers a sleek and modern aesthetic. Its hexagonal pattern adds visual interest and texture to concrete structures, helping them to stand out and make a statement. And because it's available in a range of finishes, including black and hot-dipped galvanized, it can be customized to match any design or color scheme.At McNICHOLS, we're proud to offer HEXMESHGrating as part of our extensive selection of concrete framing solutions. With 19 locations across North America, we're able to provide fast and reliable service to builders, contractors, and architects. Whether you're working on a small residential project or a large-scale industrial installation, we have the expertise and resources to help you get the job done right.In conclusion, choosing the right concrete framing materials is essential for any construction project. And when it comes to durability, reliability, and versatility, McNICHOLS Clinched HEXMESHGrating is a top choice. From its unique hexagonal grid structure to its rust-resistant galvanized steel construction, this grating offers a range of benefits that can help ensure the success of any concrete installation. So if you're looking for a top-quality concrete framing solution, look no further than HEXMESHGrating from McNICHOLS.

High-Quality SS304 Woven Wire Mesh for Various Applications

SS304 Woven Wire Mesh: A High-Quality Product for Diverse ApplicationsWoven wire mesh has become an integral part of numerous industrial and commercial applications due to its versatility and durability. One of the leading manufacturers of SS304 woven wire mesh has been the company {}. With decades of experience and a commitment to quality, they have established themselves as a trusted supplier in the industry.SS304 woven wire mesh, also known as stainless steel 304 woven wire mesh, is a popular choice for various applications due to its unique properties. It is made from high-quality stainless steel grade 304, which offers excellent corrosion resistance, good strength, and a high level of hygiene. These properties make SS304 woven wire mesh suitable for use in industries such as food processing, pharmaceuticals, chemical processing, and many others.The manufacturing process of SS304 woven wire mesh involves weaving stainless steel wires together to create a strong and durable mesh. This process is carried out with precision and attention to detail to ensure the highest quality product. The end result is a versatile material that can be used for filtration, screening, and separation of different substances.One of the key features of SS304 woven wire mesh is its ability to withstand high temperatures and harsh environmental conditions. This makes it an ideal choice for applications that require durability and reliability. Additionally, stainless steel 304 offers resistance to corrosion and oxidation, making it suitable for use in demanding industrial settings.The applications of SS304 woven wire mesh are diverse and varied. In the food processing industry, it is used for sieving, sorting, and filtering food products. Its hygiene properties and resistance to corrosion make it an ideal material for this purpose. In the pharmaceutical industry, SS304 woven wire mesh is used for screening and separating pharmaceutical ingredients, ensuring the quality and purity of the final products.In the chemical processing industry, SS304 woven wire mesh is utilized for filtration and separation of different chemicals and compounds. Its resistance to corrosion and high temperatures make it a reliable choice for these applications. Additionally, this type of wire mesh is also used in architectural and decorative applications, providing both functionality and aesthetic appeal.As a leading manufacturer of SS304 woven wire mesh, {} is committed to delivering high-quality products to meet the diverse needs of its customers. They offer a wide range of mesh sizes and specifications to cater to different requirements. With a team of experienced professionals and a state-of-the-art manufacturing facility, they ensure that their products meet the highest standards of quality and performance.The company prides itself on its customer-centric approach, providing personalized solutions and technical support to help customers find the right product for their specific needs. With a strong focus on innovation and continuous improvement, they strive to stay at the forefront of the industry and deliver cutting-edge products that meet the evolving demands of the market.In conclusion, SS304 woven wire mesh is a versatile and reliable material that finds extensive use in various industries. With its high-quality properties and the expertise of leading manufacturers like {}, this product continues to play a crucial role in a wide range of applications. As industries evolve and demand for high-quality materials increases, SS304 woven wire mesh is poised to remain a valuable and indispensable part of numerous manufacturing processes.

All You Need to Know About Welded Wire Mesh

Title: Groundbreaking Welded Wire Mesh Innovations Revolutionize the Construction IndustryIntroduction:In recent years, the construction industry has witnessed stunning advancements in materials and technologies, leading to improvements in safety, efficiency, and overall project quality. One notable innovation that has been gaining significant attention is Welded Wire Mesh. Companies around the globe, including (remove brand name), have been introducing game-changing solutions in this field, resulting in a paradigm shift in construction practices. This article will explore the latest advancements in Welded Wire Mesh technology and highlight how they are reshaping the construction industry.The Versatility of Welded Wire Mesh:Welded Wire Mesh serves as a multi-purpose construction material, offering an array of applications in various sectors. The mesh is made up of individual wires welded together to form a strong, durable, and highly flexible structure. Its versatility allows it to be utilized in a wide range of construction projects, including residential, commercial, industrial, and infrastructure developments.Enhanced Structural Integrity:One of the key benefits of Welded Wire Mesh is its ability to enhance the structural integrity of concrete structures. By providing reinforcement, it effectively counters tensile forces, preventing cracks and reducing the risk of structural failures. Moreover, Welded Wire Mesh helps distribute load-bearing capacity across larger areas, resulting in a more stable and secure overall structure.Improved Safety Measures:With safety being a top priority in any construction project, Welded Wire Mesh has emerged as a crucial solution to reinforce concrete foundations, walls, and slabs. The mesh acts as a barrier against potential hazards such as falls, flying debris, and even natural disasters. By incorporating this technology, construction companies can ensure worker safety while delivering high-quality projects.Flexibility in Design and Installation:The flexibility offered by Welded Wire Mesh allows architects and engineers to explore innovative design possibilities while ensuring structural integrity. The mesh can be easily molded and shaped to fit complex geometries, enabling the construction of unique and visually appealing structures. Additionally, its lightweight nature makes transportation and installation hassle-free, reducing overall project time and costs.Sustainability and Environmental Benefits:Welded Wire Mesh is also making strides in promoting sustainable construction practices. By utilizing recycled materials in the manufacturing process, it reduces reliance on virgin resources, leading to a significantly lower carbon footprint. Additionally, the extended lifespan and durability of structures reinforced with Welded Wire Mesh reduce the need for frequent maintenance and repairs, further contributing to environmental sustainability.Market Adoption and Industry Collaborations:As the construction industry recognizes the inherent advantages of Welded Wire Mesh, numerous companies have joined forces to foster innovation and drive the sector forward. Various research institutions and construction conglomerates are investing in research and development initiatives focused on improving Welded Wire Mesh technologies. Collaborations between manufacturers and construction companies are paving the way for groundbreaking advancements, enabling safer, more efficient, and aesthetically pleasing projects.Conclusion:Welded Wire Mesh has emerged as a transformative force within the construction industry, offering numerous benefits ranging from improved structural integrity and safety to enhanced design possibilities and sustainable practices. As companies continue to push the boundaries of innovation, Welded Wire Mesh technology will undoubtedly play a pivotal role in shaping the future of construction. With its versatile applications and continual advancements, construction projects worldwide will see increased efficiency, durability, and overall quality in the coming years.

Durable and Versatile Knitted Wire Mesh for various applications

Knitted Wire Mesh is a versatile and innovative product that has many applications across various industries. It is a type of material that is made from interlocking metal wires to form a mesh structure. This creates a strong and durable material that can be used for a wide range of purposes, from filtration and separation to reinforcement and protection.The unique design of Knitted Wire Mesh allows it to be flexible and dynamic, making it ideal for applications where traditional materials may not be suitable. It can be easily manipulated and shaped to fit specific requirements, making it a popular choice for designers and engineers.One company that is at the forefront of producing high-quality Knitted Wire Mesh is {}. With years of experience and expertise in the industry, they have established themselves as a leading provider of this innovative material. Their dedication to quality and customer satisfaction has earned them a reputation for excellence in the field.The company's Knitted Wire Mesh is manufactured using state-of-the-art technology and the highest quality materials. This ensures that their products meet the highest standards of performance and reliability. Whether it is for industrial, commercial, or residential use, {} offers a wide range of options to suit the needs of their customers.One of the key features of {}'s Knitted Wire Mesh is its versatility. It can be used for various applications, including filtration, reinforcement, insulation, and protection. Its durability and flexibility make it an ideal choice for industries such as automotive, aerospace, construction, and petrochemical.In addition to its practical uses, Knitted Wire Mesh also offers aesthetic benefits. Its unique texture and design can add a modern and stylish touch to architectural and design projects. This has made it a popular choice for interior and exterior design applications.{}'s commitment to innovation and quality has also led them to develop custom solutions for specific needs. Whether it is a unique design requirement or a specific material specification, their team of experts can work with customers to create a tailored solution that meets their exact needs.Furthermore, the company places a strong emphasis on sustainability and environmental responsibility. Their Knitted Wire Mesh is manufactured using processes that minimize waste and energy consumption, making it a sustainable choice for environmentally conscious customers.In conclusion, Knitted Wire Mesh is a versatile and innovative material that has a wide range of applications across various industries. With its flexibility, durability, and aesthetic appeal, it has become a popular choice for designers, engineers, and manufacturers. {}'s dedication to quality and customer satisfaction has made them a trusted provider of high-quality Knitted Wire Mesh. As the demand for this innovative material continues to grow, {} is well-positioned to lead the way in the industry.

New Steel Grating Innovations to Improve Safety and Durability

Steel Grating: Revolutionizing the Construction IndustryThe construction industry has witnessed a remarkable and steady growth over the years. As buildings continue to reach unprecedented heights, it becomes crucial to ensure the safety and stability of these structures. One indispensable component that plays a significant role in this regard is steel grating. Steel grating has proven to be a game-changer, revolutionizing the construction industry with its exceptional strength, durability, and versatility.[Company Introduction]With a firm commitment to delivering high-quality products and a staunch vision for industry innovation, [Company Name] has emerged as a leading manufacturer and global supplier of steel grating solutions. Our company prides itself on a legacy of excellence, spanning several decades, wherein we have consistently provided our customers with unmatched products and services.Since our inception, we have remained dedicated to research and development, constantly establishing ourselves at the forefront of technological advancements in the steel grating industry. Today, our extensive range of products, custom-designed solutions, and unwavering commitment to customer satisfaction sets us apart from our competitors.Built for Strength and DurabilitySteel grating stands out for its exceptional strength and durability, making it an indispensable component in the construction industry. Manufactured using high-quality steel, it possesses immense load-bearing capacity, ensuring the safety of workers and residents alike. The inherent strength of steel grating allows for the creation of stable platforms and walkways, while its open-grid design facilitates the drainage of water, preventing potential hazards such as slipping.Beyond its strength, steel grating is resistant to corrosion, chemicals, and extreme weather conditions. This robust nature ensures a longer lifespan, reducing maintenance costs and enhancing the overall structural integrity of buildings. Our commitment to quality control, along with the utilization of cutting-edge manufacturing techniques, guarantees that our steel grating products meet the highest industry standards, surpassing customer expectations.Unlimited VersatilityOne of the remarkable aspects of steel grating is its versatility. It finds applications in a wide range of industries, including construction, manufacturing, energy, transportation, and more. Whether it’s platforms, mezzanines, stairs, fences, or even decorative elements, steel grating offers unparalleled flexibility, allowing for endless possibilities in architectural design.With an array of available patterns, materials, and finishes, the aesthetic appeal of steel grating can be seamlessly integrated into any building or infrastructure project. It can be galvanized, painted, or left untreated, providing options to suit various design concepts while maintaining functionality.Environmental Advantages and SustainabilityIn addition to its strength and versatility, steel grating also boasts environmental advantages, contributing to sustainability efforts in the construction industry. Steel is one of the most recycled materials globally, and the majority of steel grating is composed of recycled steel. By utilizing steel grating in construction projects, companies can reduce their carbon footprint and support sustainable practices.Furthermore, steel grating's lightweight nature translates into efficient transportation and installation, reducing energy and labor costs. Its low maintenance requirements and long lifespan further contribute to sustainability efforts by minimizing waste and the need for frequent replacements.ConclusionSteel grating's remarkable features, coupled with its inherent strength, durability, versatility, and environmental advantages, have propelled it to the forefront of the construction industry. With companies like [Company Name] leading the way in manufacturing high-quality steel grating solutions, builders and architects can now construct safer, more durable, and aesthetically pleasing structures.As the world continues to evolve technologically and architecturally, steel grating stands as a testament to innovation and progress in the construction industry. It is not just a significant component but an essential element that paves the way for safer, sustainable, and visually appealing construction practices.

Crimped Wire Mesh for Mining and Industrial Applications - Galvanized and Stainless Steel Options Available

for different industries and applications.Crimped Wire Mesh: A Versatile Solution for Different Industries and ApplicationsCrimped wire mesh is a type of woven wire mesh used in various industrial applications, such as mining, construction, agriculture, and filtration. It is made by weaving pre-crimped wires into a mesh pattern, which provides stability and strength to the mesh.Crimped wire mesh comes in different materials, such as stainless steel, galvanized steel, aluminum, and brass. Each material offers unique features and benefits that make it suitable for specific applications. For instance, stainless steel crimped wire mesh is corrosion-resistant and durable, making it ideal for outdoor and harsh environments. Galvanized crimped wire mesh, on the other hand, is more affordable and has better rust resistance than plain steel wire mesh.In this blog, we will discuss the various industries and applications that use crimped wire mesh, highlighting the benefits and advantages of this versatile product.Mining IndustryCrimped wire mesh is extensively used in the mining industry for screening and separating minerals and ores. The mesh is woven with high-tensile wires that can withstand the abrasive and corrosive environment of mining operations. The mesh size and wire diameter can be customized to meet specific requirements for particle size analysis and classification.Construction IndustryCrimped wire mesh is widely used in the construction industry for reinforcement purposes. It is used as a bonding material in concrete structures to provide tensile strength and stability. The mesh can also be used for decorative purposes, such as fencing, partitions, and cladding.Agriculture IndustryCrimped wire mesh is used in the agriculture industry for various purposes, including poultry fencing, livestock cages, and crop protection. The mesh provides a strong and durable barrier that keeps animals and pests out while allowing air and light to circulate.Filtration IndustryCrimped wire mesh is used in the filtration industry for liquid and gas filtration. The mesh is woven with fine wires that can capture and retain particles down to the micrometer level. The mesh can be made of different materials and configurations to meet specific filtration requirements.Other ApplicationsCrimped wire mesh is also used in other industries and applications, such as automotive, aerospace, and architecture. In the automotive industry, it is used for radiator grilles, speaker covers, and airbag screens. In the aerospace industry, it is used for engine filters, aircraft vents, and debris shields. In architecture, it is used for balustrades, screens, and shading devices.ConclusionCrimped wire mesh is a versatile and essential product that finds use in several industries and applications. It provides strength, stability, and durability to various structures and devices, making it a reliable and cost-effective solution for many applications. Choosing the right material, mesh size, and wire diameter is crucial to ensure that the crimped wire mesh meets the specific requirements and conditions of each application. Anping Huansi Wire Mesh Products Co., Ltd. offers high-quality crimped wire mesh products that meet international standards and specifications. Contact us for more information about our products and services.

Durable Steel Grating: A Popular Choice for Industrial Applications

Steel Grating Industry Leading Manufacturer: Providing High-Quality Products for Various ApplicationsIn the world of construction and industrial applications, steel grating is an essential component that provides strength, durability, and stability to various structures. The proper selection of steel grating can make a significant difference in the performance and longevity of a project. As such, it is crucial to source steel grating from a reputable and reliable manufacturer. One such industry-leading manufacturer is {company name}.{Company name} is a renowned manufacturer of steel grating products, serving a wide range of industries including construction, oil and gas, mining, and infrastructure. Their commitment to quality, innovation, and customer satisfaction has earned them a strong reputation in the industry.With decades of experience, {company name} has perfected the art of producing high-quality steel grating products that meet and exceed industry standards. Their products are designed to withstand heavy loads, harsh environments, and fluctuating temperatures, making them ideal for a variety of applications.One of the key factors that set {company name} apart from other manufacturers is their state-of-the-art production facility. Equipped with the latest technology and machinery, the facility is capable of producing steel grating products with precision and efficiency. This ensures that every product that leaves their facility is of the highest quality and consistency.In addition to their advanced production capabilities, {company name} places a strong emphasis on research and development. They continuously invest in new technologies and materials to improve their products and stay ahead of industry trends. This commitment to innovation allows them to offer cutting-edge solutions that meet the evolving needs of their customers.{Company name} offers a wide range of steel grating products, including welded steel bar grating, press-locked steel grating, heavy-duty steel grating, and more. These products come in various materials, such as carbon steel, stainless steel, and aluminum, as well as different surface treatments to suit specific project requirements.Furthermore, {company name} takes pride in their ability to customize steel grating products to meet unique project specifications. Whether it's a special size, shape, or load-bearing capacity, their team of experts can work closely with customers to develop custom solutions that fit their exact requirements.Another aspect that sets {company name} apart is their commitment to sustainability and environmental responsibility. They adhere to strict environmental standards in their production processes and strive to minimize their carbon footprint. This is achieved through the efficient use of resources, responsible waste management, and the implementation of eco-friendly practices.Aside from their product offerings, {company name} is also known for their exceptional customer service. Their team of dedicated professionals is committed to providing comprehensive support to customers throughout the entire project lifecycle. From initial consultation to post-sale assistance, they go the extra mile to ensure that customers are fully satisfied with their experience.In conclusion, {company name} is a trusted industry leader in the manufacturing of steel grating products. With their commitment to quality, innovation, and customer satisfaction, they continue to be a preferred choice for construction and industrial projects around the world. By offering high-quality products, advanced production capabilities, custom solutions, and outstanding customer service, {company name} is poised to remain at the forefront of the steel grating industry for years to come.