Durable and Versatile Knitted Wire Mesh for Various Applications

By:Admin

Established in {}, {} has been a pioneer in the field of knitted wire mesh production. Their state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing them to produce knitted wire mesh products that meet the highest standards of quality and performance. The company's team of experienced engineers and technicians work tirelessly to develop innovative solutions and customized products to meet the unique needs of their clients across various industries. From aerospace and automotive to petrochemical and electronics, {} has established a strong reputation for delivering reliable and cost-effective knitted wire mesh solutions.

One of the key factors that set {} apart from its competitors is their unwavering commitment to research and development. Their R&D team is constantly exploring new materials, designs, and manufacturing techniques to improve the performance and efficiency of their knitted wire mesh products. This dedication to innovation has led to the development of advanced knitted wire mesh solutions that offer superior strength, flexibility, and corrosion resistance, making them ideal for even the most demanding applications. With a focus on sustainability and environmental responsibility, {} also invests in eco-friendly materials and processes, ensuring that their knitted wire mesh products are not only high-performing but also environmentally friendly.

In addition to their cutting-edge manufacturing capabilities, {} also prides itself on its comprehensive quality control measures. Every knitted wire mesh product undergoes rigorous testing and inspection to ensure that it meets the highest industry standards for performance, reliability, and safety. This commitment to quality has earned {} various certifications and accreditations, further solidifying their position as a trusted and reputable supplier of knitted wire mesh solutions.

One of the key advantages of {}'s knitted wire mesh products is their versatility. Whether it's for industrial filtration, liquid and gas separation, noise and vibration control, or protective shielding, {} offers a diverse range of knitted wire mesh products to suit a wide array of applications. With the ability to customize their products to meet specific requirements, {} has become the go-to partner for companies looking for reliable and tailor-made knitted wire mesh solutions.

As a customer-focused company, {} also places great emphasis on providing exceptional service and support to their clients. From initial consultation and product selection to after-sales technical assistance, their team of experts is dedicated to ensuring that their customers receive the best possible knitted wire mesh solutions to meet their needs. With a focus on building long-term relationships and delivering value to their clients, {} has earned the trust and loyalty of customers across the globe.

In conclusion, knitted wire mesh has become an indispensable component in a wide range of industries, and {} has established itself as a leading provider of high-quality knitted wire mesh solutions. With their advanced manufacturing capabilities, commitment to innovation, and dedication to quality and customer satisfaction, {} continues to set the standard for excellence in the knitted wire mesh industry. Whether it's for filtration, separation, protection, or reinforcement, companies can rely on {} to deliver reliable, efficient, and cost-effective knitted wire mesh solutions that meet their unique needs.

Company News & Blog

6 Benefits of Installing a Chain Link Fence on Your Property

FOR IMMEDIATE RELEASEChain Link Fence Company Offers Durable and Affordable Fencing Solutions for Residential and Commercial PropertiesAs property owners seek reliable and cost-effective solutions for securing their residential and commercial properties, {Company Name} offers a wide range of chain link fence options designed to meet their needs. With a strong focus on durability, affordability, and installation flexibility, the company has established itself as a premier provider of high-quality fencing solutions.{Company Name} specializes in the manufacture and installation of chain link fences, offering a variety of options to suit the specific needs of residential and commercial properties. Whether it's securing a backyard, a construction site, or a commercial facility, the company's chain link fences are designed to provide security, privacy, and peace of mind.One of the key features of {Company Name}'s chain link fences is their durability. Constructed from high-quality materials, including galvanized steel and vinyl coating, the fences are built to withstand harsh weather conditions and everyday wear and tear. This ensures that property owners can enjoy long-lasting protection for their properties without having to worry about frequent repairs or replacements.In addition to their durability, {Company Name}'s chain link fences are also known for their affordability. By leveraging efficient manufacturing processes and strategic partnerships with suppliers, the company is able to offer cost-effective fencing solutions without compromising on quality. This makes their fences an attractive option for property owners who are looking to maximize their investment without breaking the bank.Another advantage of {Company Name}'s chain link fences is their installation flexibility. Whether it's a small residential property or a large commercial complex, the company's expert team can customize the fencing solution to fit the specific requirements of the project. With a focus on precision and efficiency, the installation process is seamless and minimally disruptive, allowing property owners to quickly and easily enjoy the benefits of their new chain link fence.Beyond their product offerings, {Company Name} is committed to providing exceptional customer service to all of their clients. From the initial consultation to the final installation, the company's team of experts is dedicated to delivering a seamless and stress-free experience for every customer. This includes providing professional guidance on fence selection, offering transparent pricing and timelines, and ensuring that the final product exceeds expectations.With a strong track record of customer satisfaction and an unwavering commitment to quality, {Company Name} has established itself as a trusted provider of chain link fences for residential and commercial properties. Whether it's securing a backyard, a construction site, or a commercial facility, the company's durable, affordable, and flexible fencing solutions are the go-to choice for property owners looking for reliable protection.For more information about {Company Name} and their chain link fence offerings, visit their website at www.example.com or contact them directly at (555) 123-4567.Media Contact:John SmithMarketing Manager{Company Name}Email: [email protected]: (555) 123-4567

High-Quality Crimped Wire Mesh for Various Industrial Applications

Crimped Wire Mesh: A Versatile Solution for Various ApplicationsCrimped wire mesh is a type of woven wire mesh that is used in various industrial and commercial applications. It is an essential component in industries such as mining, construction, agriculture, and transportation. The crimped wire mesh is known for its strength, durability, and versatility, making it an ideal solution for a wide range of applications.One company that specializes in the manufacturing and distribution of crimped wire mesh is {}. {} is a leading manufacturer and supplier of wire mesh products, including crimped wire mesh, welded wire mesh, and woven wire mesh. Established in 2008, {} has become a trusted name in the wire mesh industry, known for its high-quality products and exceptional customer service.The crimped wire mesh manufactured by {} is made from high-quality materials, ensuring its strength and durability. The company uses advanced weaving techniques to create a product that is resistant to wear and tear, corrosion, and high temperatures. This makes {}'s crimped wire mesh suitable for applications that require robust and reliable materials.One of the key advantages of crimped wire mesh is its flexibility. It can be easily customized to meet specific requirements, making it suitable for a wide range of applications. In the mining industry, crimped wire mesh is used for screening and separating materials, such as coal, stone, and ore. Its high tensile strength and abrasion resistance make it an ideal choice for this demanding application.In the construction industry, crimped wire mesh is used for reinforcing concrete and masonry structures. It provides additional strength and stability, improving the overall integrity of the structure. The durability of crimped wire mesh also makes it suitable for outdoor applications, such as fencing and landscaping.Agricultural applications also benefit from the use of crimped wire mesh. It is commonly used for animal enclosures, including poultry cages, animal pens, and garden fencing. The flexibility and strength of crimped wire mesh make it an ideal solution for containing animals and protecting crops from wildlife.Transportation and automotive industries also rely on crimped wire mesh for various applications. It is used for manufacturing vehicle grilles, radiator guards, and air intake screens. The strength and durability of crimped wire mesh make it an ideal material for protecting essential components of vehicles.With its wide range of applications and benefits, crimped wire mesh has become an essential component in various industries. The manufacturing and distribution of high-quality crimped wire mesh play a crucial role in ensuring the safety, reliability, and performance of industrial and commercial applications.As a leading supplier of wire mesh products, {} is committed to providing its customers with the highest quality crimped wire mesh. The company's state-of-the-art manufacturing facilities and experienced team ensure that its products meet the highest industry standards. {}'s dedication to excellence and customer satisfaction has made it a trusted partner for businesses across diverse industries.In conclusion, crimped wire mesh is a versatile and indispensable solution for a wide range of industrial and commercial applications. With its strength, durability, and flexibility, crimped wire mesh from {} is a reliable choice for businesses seeking high-quality wire mesh products. As the demand for crimped wire mesh continues to grow, {} remains committed to meeting the needs of its customers and contributing to the success of various industries.

60 ft Brown Chain Link Fence with Gates, Posts and Top Rails for Sale in Kingston

, Decks and Fences, Kingston, Kijiji, Removal, Posts, Top Rails, Gates, Black, Swaps, Delivery.Chain Link Fences - A Popular and Durable Option for Your PropertyWhen it comes to fencing, there are a lot of options available in the market. However, one of the most popular and widely used options is Chain Link Fences. Not only are they durable and long-lasting, but they also offer a number of practical benefits. In this blog post, we will explore why Chain Link Fences are a great option for your property and how you can benefit from them.Durability and StrengthOne of the key benefits of Chain Link Fences is that they are incredibly strong and durable. Made of galvanized steel wire, they can withstand harsh weather conditions and heavy impact. Whether you live in an area with strong winds or heavy rainfall, a Chain Link Fence can provide you with the peace of mind that your property is protected.Security and PrivacyChain Link Fences are also great for providing security and privacy to your property. The tight mesh of the fence prevents people from easily seeing inside your property, allowing you to maintain your privacy. Additionally, the height of the fence can be adjusted to suit your specific needs, providing an added level of security.Easy MaintenanceAnother great benefit of Chain Link Fences is that they are easy to maintain. Unlike other types of fences that require regular upkeep, Chain Link Fences require very little maintenance. Due to their sturdy construction, they do not easily break or bend, and they do not require painting or staining. A simple wash with soap and water is all that is needed to keep them looking good as new.CustomizableChain Link Fences are also highly customizable, allowing you to choose from a variety of colors and designs. This makes it easy to find a fence that matches the aesthetic of your property. Additionally, they come in a range of heights, giving you the flexibility to choose the height that best suits your needs.AffordableFinally, Chain Link Fences are highly affordable when compared to other types of fences. This makes them a great option for homeowners looking to balance cost with durability and practicality. Additionally, since they require very little maintenance, they are a cost-effective investment in the long run.In conclusion, Chain Link Fences are a great option for anyone looking for a durable, secure, and customizable fencing option. Whether you are looking to protect your property or simply add some privacy, a Chain Link Fence can provide you with the peace of mind that comes with knowing your property is secure. If you are in the Kingston area, be sure to check out Kijiji for great deals on Chain Link Fences, including removal, posts, top rails, and gates.

High-Quality Fencing Mesh for Your Property

Fencing Mesh has been a popular choice for homeowners, businesses, and contractors looking to secure their properties and create boundaries. It is a versatile and durable fencing solution that provides security and aesthetic appeal. With its wide range of applications, it has become a go-to option for a variety of projects.Fencing Mesh is an essential product for any construction project, providing high-quality solutions for fencing needs. The company has been a leader in the industry for over 20 years, providing innovative and reliable products to customers across the country. Their commitment to quality and customer satisfaction has earned them a reputation as a trusted supplier in the fencing industry.The company offers a wide range of fencing mesh products, including chain link, welded wire, and expanded metal mesh. These products are available in a variety of materials, including galvanized steel, stainless steel, and aluminum, to meet the specific needs of each customer. The diverse range of options allows customers to choose the best fencing solution for their unique project requirements.One of the key advantages of Fencing Mesh is its durability. The products are designed to withstand harsh weather conditions, heavy impacts, and potential damage. This makes them a reliable and long-lasting solution for any fencing project. The company's commitment to quality ensures that customers receive a durable and high-performance product that will last for years to come.In addition to durability, Fencing Mesh offers a high level of security. The products are designed to provide a strong and impenetrable barrier, offering protection and peace of mind to property owners. This makes them an ideal choice for securing homes, businesses, industrial facilities, and construction sites.The versatility of Fencing Mesh is another notable feature. The products can be used in a wide range of applications, including perimeter fencing, security fencing, animal enclosures, and decorative fencing. This flexibility makes Fencing Mesh an ideal choice for a variety of projects, from residential to commercial and industrial.The company's dedication to customer satisfaction is evident in its commitment to providing exceptional service. Their team of knowledgeable and experienced professionals is always on hand to offer support and guidance to customers. Whether it's helping with product selection, providing technical advice, or assisting with installation, the company is dedicated to ensuring that customers have a positive experience.As a leader in the fencing industry, the company is committed to sustainability and environmental responsibility. They adhere to strict environmental standards and use eco-friendly manufacturing processes to reduce their carbon footprint. This commitment to sustainability ensures that customers can feel good about choosing Fencing Mesh for their projects.In summary, Fencing Mesh is a reliable, durable, and versatile fencing solution that meets the diverse needs of customers across the country. With a commitment to quality, customer satisfaction, and sustainability, the company has established itself as a trusted leader in the industry. Whether for residential, commercial, or industrial applications, customers can rely on Fencing Mesh for all their fencing needs.

Essential Guide to Choosing the Best Binding Wires for Your Needs

In today's fast-paced and ever-evolving world, companies are constantly seeking innovative solutions to streamline their operations and maximize efficiency. One such solution that has become indispensable in various industries is the versatile and essential binding wire. From construction to packaging, binding wire plays a crucial role in securely holding materials together, making it an invaluable tool for businesses across the board.Company ABC is a leading provider of binding wire solutions, catering to the diverse needs of its clients with a wide range of high-quality products. With a strong focus on innovation and customer satisfaction, Company ABC has established itself as a trusted name in the industry, delivering top-notch binding wire solutions to meet the unique requirements of its clients.One of the key features that sets Company ABC's binding wire apart is its exceptional durability and tensile strength. This ensures that the wire can withstand the rigors of various applications, from heavy-duty construction projects to delicate packaging needs. In addition, Company ABC offers a variety of wire diameters and lengths to accommodate different binding requirements, providing customers with the flexibility they need to tackle a wide range of projects.Moreover, Company ABC's commitment to sustainability sets it apart from its competitors. The company recognizes the importance of environmental responsibility and has implemented eco-friendly practices in its manufacturing processes. As a result, customers can rest assured that they are not only receiving top-quality products but also contributing to a greener, more sustainable future.Furthermore, Company ABC's dedication to customer satisfaction is evident in its excellent customer service and support. The company's team of experts is readily available to provide guidance and assistance to clients, ensuring that they receive the right binding wire solution for their specific needs. Whether it's a custom order or technical advice, Company ABC goes the extra mile to ensure that its customers are fully satisfied with their experience.In recent news, Company ABC has announced the launch of a new and improved binding wire product line, designed to further enhance the efficiency and reliability of its offerings. The new line incorporates advanced technologies and materials to deliver even greater performance, making it an ideal choice for businesses looking to streamline their operations and improve their bottom line.This latest development is a testament to Company ABC's ongoing commitment to innovation and excellence. By continually pushing the boundaries of what is possible with binding wire solutions, the company is helping its clients stay ahead of the curve and achieve their goals with confidence. With the new product line, customers can expect enhanced durability, strength, and versatility, providing them with the peace of mind that their binding needs are in good hands.In conclusion, binding wire remains an indispensable tool for businesses across various industries, and Company ABC continues to lead the way with its exceptional product offerings and unwavering commitment to customer satisfaction. As the company introduces its new and improved binding wire product line, it is evident that Company ABC is dedicated to providing its clients with the best-in-class solutions they need to succeed in today's competitive marketplace. With a focus on quality, sustainability, and innovation, Company ABC is poised to continue setting the standard for binding wire excellence for years to come.

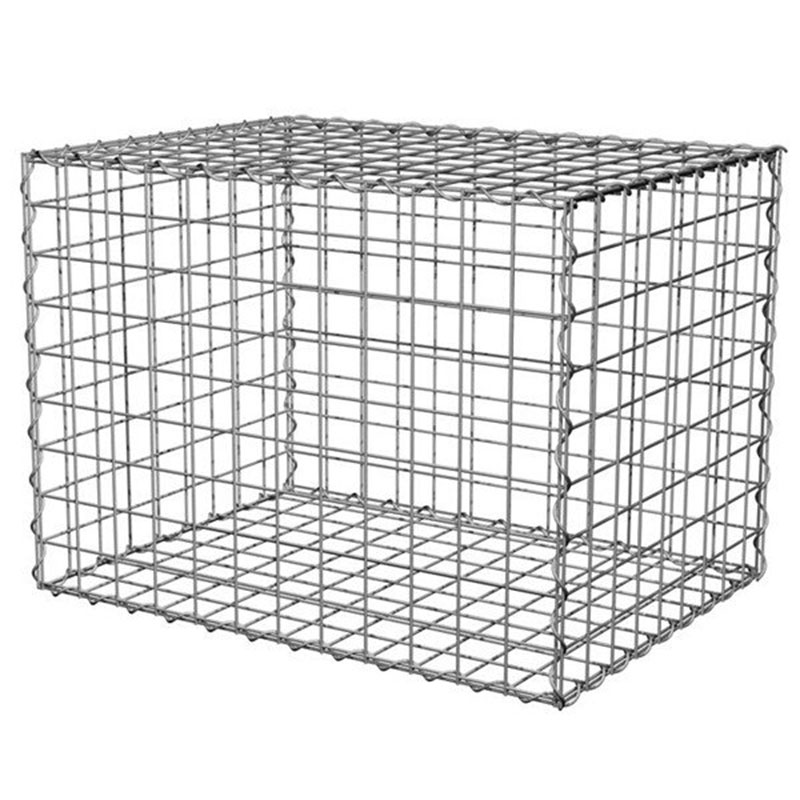

Gabion Baskets Used to Build Access Track Along Train Station

and Access Track to improve search engine optimization.Gabion Retaining Walls and Access TracksGabion retaining walls have become popular due to their cost-effective and environmentally friendly benefits. The use of gabion baskets in retaining walls is now prevalent in many construction projects.One example of how gabion baskets can be used is in the construction of access tracks. Access tracks are essential in industrial developments as they provide a safe and efficient way for vehicles to move around. Access tracks can also be used in train stations to provide a route for maintenance vehicles to access the track.Gabion baskets are ideal for constructing retaining walls for access tracks as they are strong and durable. The nature of gabion baskets also makes them perfect for retaining the site boundary along the length of an access road.The use of gabion retaining walls in access tracks has many benefits. The walls are made up of wire mesh cages filled with rocks and other materials. The holes in the baskets allow water to flow through, reducing pressure on the wall and preventing erosion.Gabion retaining walls are also eco-friendly as they use natural materials with a low carbon footprint. The materials can be sourced locally, reducing transportation costs and emissions.Another benefit of gabion retaining walls is their flexibility. They can be contoured to fit the shape of the land, providing a smooth and safe access track. The flexibility of the baskets also allows for expansion and contraction with temperature changes, preventing cracking and damage.The installation of gabion retaining walls for access tracks is also straightforward. The baskets are easy to transport and can be assembled on site, reducing construction times and costs.In conclusion, the use of gabion retaining walls in access tracks is an excellent choice for industrial developments and train stations. The benefits of gabion retaining walls, including their strength, durability, and eco-friendliness, make them an ideal choice for constructing retaining walls for access tracks. Their flexibility and ease of installation also make them a popular choice for many construction projects.

High-Quality Woven Wire Mesh for Polymer Extruder Screens: Stainless Steel Square Mesh Cloth and Sieving Screens Available

and Polymer Extruder Screens.If you are looking for a reliable and high-quality woven wire mesh supplier, look no further than ANPING COUNTY DONGJIE WIREMESH PRODUCTS CO., LTD. As a leading manufacturer and supplier of woven wire mesh products, we pride ourselves on delivering exceptional quality and outstanding customer service.At our factory, we produce a wide range of woven wire mesh products including plain weave stainless steel woven wire mesh cloth, and square metal woven sieving screen filter wire mesh. Our products are made from high-quality materials, including SS304 and SS316 stainless steel, ensuring that they are durable and long-lasting.One of our most popular products is our polymer extruder screens. These screens are used in the polymer extrusion process to filter out impurities and keep the final product clean. Our polymer extruder screens are made from high-quality stainless steel woven wire mesh, and are designed to provide exceptional performance, durability and longevity.In addition to our standard product range, we also offer custom-designed woven wire mesh products to meet the specific requirements of our customers. Our team of experienced engineers and designers works closely with our clients to understand their needs and requirements, and to create customized solutions that meet their specific needs.At ANPING COUNTY DONGJIE WIREMESH PRODUCTS CO., LTD., we are committed to providing our customers with the highest level of quality, reliability, and performance. Whether you need woven wire mesh for industrial filtration applications, or for architectural and decorative purposes, we have the resources and expertise to meet your needs.So why wait? Contact us today to learn more about our woven wire mesh products, and how we can help you achieve your goals!

Durable and Secure Metal Bar Grating for Floors: A Complete Guide

Metal Bar Grating For Floor is a vital component in various industrial and commercial settings, offering durability, strength, and safety. These grating systems are used in a wide range of applications, including flooring, walkways, and platforms, providing a secure and stable surface for employees and equipment. One company that has been leading the industry in producing high-quality metal bar gratings is {}.{} is a renowned manufacturer of metal bar gratings, offering a comprehensive range of products designed to meet the diverse needs of their customers. With a strong focus on quality, innovation, and customer satisfaction, the company has established itself as a trusted source for top-of-the-line grating solutions.The metal bar gratings produced by {} are constructed using the highest quality materials, including stainless steel, aluminum, and carbon steel. This ensures that the grating systems are able to withstand heavy loads, harsh environmental conditions, and constant foot traffic. With a commitment to excellence, {} consistently delivers products that meet or exceed industry standards, making them a preferred choice for a wide range of applications.One of the key advantages of {}'s metal bar grating for floor is its versatility. The grating systems are available in various configurations, including welded, pressure-locked, and swaged, allowing for customization to suit specific project requirements. This flexibility makes {}'s gratings suitable for use in manufacturing facilities, industrial plants, commercial buildings, and outdoor spaces.In addition to their practical applications, {}'s metal bar gratings are also designed with safety in mind. The grating systems feature a unique surface pattern that provides excellent traction, reducing the risk of slips and falls. This is particularly important in environments where moisture, oils, or other slippery substances may be present, ensuring the safety of employees and visitors.Furthermore, {}'s metal bar gratings are designed to facilitate easy installation and maintenance. The grating systems are lightweight and easy to handle, reducing the time and labor required for installation. Additionally, the materials used in the construction of the grating systems are resistant to corrosion and rust, minimizing the need for ongoing maintenance and preserving the aesthetics of the flooring.With a dedication to customer satisfaction, {} offers comprehensive support to their clients, including expert guidance on product selection, customization options, and technical assistance. This commitment to service has earned the company a reputation for reliability and professionalism, further solidifying their position as a leader in the industry.In conclusion, {}'s metal bar grating for floor is a versatile, durable, and safe solution for a wide range of applications. With a focus on quality, innovation, and customer satisfaction, {} has established itself as a trusted source for top-of-the-line grating solutions. Their commitment to excellence, safety, and customer service makes them a preferred choice for industrial and commercial projects. For all your metal bar grating needs, {} is the company you can rely on.

Top 5 Benefits of Using Crimped Wire Mesh in Industrial Applications

Crimped Wire Mesh Revolutionizing Industrial ApplicationsWire mesh has been a ubiquitous material in many industries worldwide, utilized for an array of purposes including filtration, screening, sieving, and fencing. However, a breakthrough in wire mesh technology has emerged, offering enhanced quality and durability that has revolutionized industrial applications. Leading the charge in this innovation is a company that has been in the forefront of wire mesh manufacturing for several decades. With their state-of-the-art production facilities and commitment to excellence, they have introduced the next generation of wire mesh - Crimped Wire Mesh.Crimped Wire Mesh is a versatile, durable, and cost-effective solution for a wide range of industrial applications. Unlike traditional wire mesh, which consists of straight wires woven together, Crimped Wire Mesh incorporates a zig-zag pattern, adding rigidity and strength to the material. This unique crimping technique enhances the structural integrity of the mesh, making it resistant to bending, breaking, and deformation. This cutting-edge technology ensures that the wire mesh maintains its shape and strength even under heavy loads or extreme conditions.The superior quality of Crimped Wire Mesh translates into numerous advantages across various industries. In the mining and quarrying sector, it is widely used for screening and separating minerals, stone aggregates, or any other materials. The sturdy construction and precise openings of the mesh allow for efficient sorting and size classification, enabling optimal resource utilization. Additionally, the durability and corrosion resistance of Crimped Wire Mesh make it ideal for use in harsh environments, providing reliable performance over an extended lifespan.The construction industry has also embraced Crimped Wire Mesh due to its versatility and strength. It is commonly employed for reinforcing concrete structures, adding stability and tensile strength to the building materials. The crimped pattern ensures that the wire mesh remains firmly embedded in the concrete, preventing cracks and enhancing the overall integrity of the structure. Moreover, the mesh can be customized to match specific project requirements, making it a preferred choice for architects and engineers.Furthermore, Crimped Wire Mesh finds applications in the automotive and transportation sectors, playing a vital role in vehicle manufacturing. Its robust design and high tensile strength make it an excellent material for fabricating radiator grilles, protective screens, and exhaust system components. The mesh's ability to withstand extreme temperatures and its resistance to corrosion contribute to the longevity and performance of these crucial automotive parts.Not limited to heavy industries, Crimped Wire Mesh also offers solutions for everyday household needs. In the agricultural sector, it is utilized in fencing and enclosures, providing security and protection for livestock and crops. Moreover, it is an indispensable component of poultry cages and aviaries, ensuring the safety and well-being of birds. Its versatility extends to domestic applications such as window screens, vents, and pet enclosures, where it offers durability and longevity, while also allowing air circulation and visibility.With its commitment to product excellence and customer satisfaction, the manufacturer behind Crimped Wire Mesh has become a global leader in wire mesh technology. Their state-of-the-art production facilities, coupled with rigorous quality control measures, ensure that their products consistently meet the highest industry standards. They also offer a wide range of customization options, allowing customers to tailor the mesh specifications to their specific requirements.In conclusion, Crimped Wire Mesh has revolutionized industrial applications, offering enhanced durability, strength, and versatility to various industries. Its unique crimping technology ensures superior performance, making it the go-to solution for tasks ranging from mining and construction to agriculture and automotive. As industries continue to evolve, Crimped Wire Mesh is poised to play an increasingly crucial role in shaping a range of applications.

5 Benefits of Installing a Chain Link Fence for Your Property

Chain link fencing is a versatile and reliable option for residential, commercial, and industrial properties. With its durable construction and low-maintenance requirements, it is no wonder that it has become a popular choice for property owners looking to secure their perimeter while still maintaining visibility and aesthetic appeal.The company, with a history of over 30 years in the fencing industry, has established itself as a reputable supplier and installer of chain link fencing. Their commitment to quality, customer satisfaction, and attention to detail has set them apart from their competitors, making them the go-to choice for all fencing needs.One of the key advantages of chain link fencing is its durability. Made from galvanized steel, it can withstand harsh weather conditions, resist corrosion, and provide long-lasting protection for any property. This makes it an ideal option for outdoor spaces, providing security and peace of mind for property owners.Moreover, chain link fencing is also a cost-effective solution. With its relatively low upfront cost and minimal maintenance requirements, it offers great value for money compared to other fencing options. This makes it an attractive choice for budget-conscious individuals and businesses looking to secure their properties without breaking the bank.In addition to its durability and cost-effectiveness, chain link fencing also offers great flexibility in terms of design and customization. It can be easily tailored to fit any property's specific requirements, whether it's a residential backyard, a commercial property, or an industrial site. It can be customized in terms of height, color, and additional features such as privacy slats or barbed wire, providing a tailored solution for any fencing needs.The company specializes in providing customized chain link fencing solutions to meet their clients' unique needs. Their team of experienced professionals works closely with each client to understand their requirements and preferences, ensuring that the final product meets and exceeds their expectations. From the initial design and planning phase to the installation and post-service support, the company is dedicated to delivering top-quality results and ensuring customer satisfaction every step of the way.Furthermore, the company's expertise extends beyond just installing chain link fencing. They also offer maintenance and repair services to ensure that their clients' fencing remains in top condition for years to come. This further adds to the value and peace of mind that their clients experience, knowing that their investment is being cared for by a knowledgeable and reliable team.In conclusion, chain link fencing is a durable, cost-effective, and customizable solution for securing any property. With the company's extensive experience and commitment to quality, they have become a trusted provider of chain link fencing solutions for residential, commercial, and industrial clients. Their dedication to customer satisfaction and top-notch service makes them the ideal choice for anyone looking to invest in a reliable and long-lasting fencing solution.