Discover the Benefits of Knitted Wire Mesh for Various Applications

By:Admin

{Company} is a leading provider of knitted wire mesh, a versatile and high-quality material that is used in a wide range of applications across various industries. With years of experience and expertise in the field, {Company} has established itself as a trusted source for knitted wire mesh products that meet the highest standards of quality and performance.

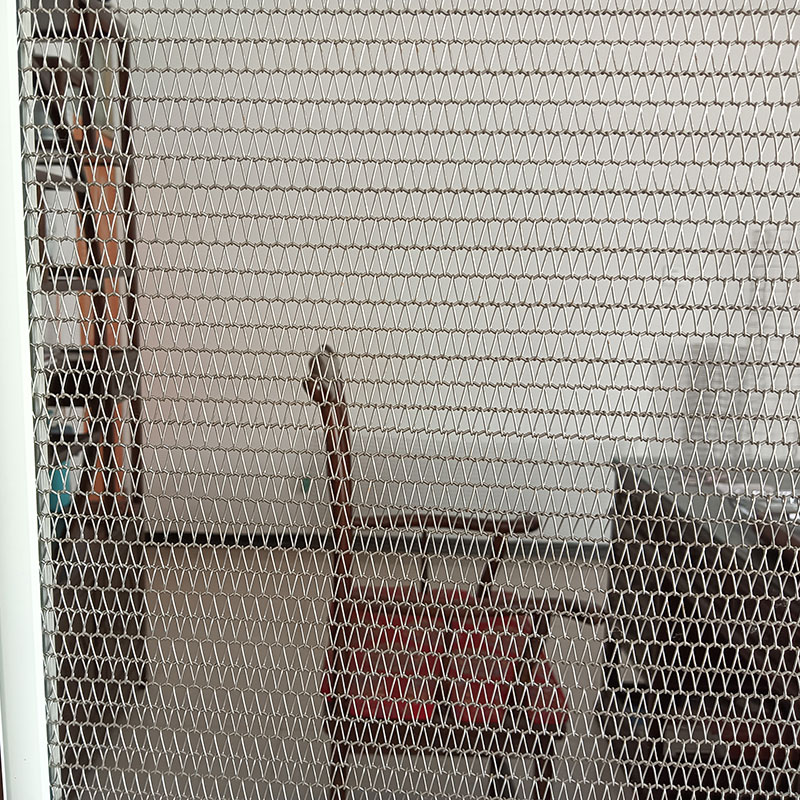

Knitted wire mesh is a type of wire fabric that is produced by knitting or looping wires together. This unique construction gives the mesh its flexibility and durability, making it ideal for applications where strength and resilience are crucial. The mesh can be manufactured from different materials, including stainless steel, copper, and aluminum, each offering its own set of properties and advantages.

One of the key benefits of knitted wire mesh is its ability to provide excellent filtration and separation capabilities. The interlocking wire loops create a uniform and consistent mesh structure that is highly effective in capturing and retaining solid particles, liquids, and gases. This makes knitted wire mesh an ideal choice for applications such as filtration, separation, and straining in industries such as automotive, aerospace, and chemical processing.

In addition to its filtration capabilities, knitted wire mesh is also widely used for its excellent sealing and gasketing properties. The flexible and compressible nature of the mesh allows it to conform to irregular surfaces and provide a tight seal, making it suitable for applications such as gaskets, seals, and packing materials in industrial equipment and machinery.

Another important application of knitted wire mesh is in the field of demisting and mist elimination. The mesh is highly efficient in capturing and removing liquid droplets from gas streams, making it a critical component in processes such as air and gas purification, chemical processing, and environmental control.

{Company} offers a wide range of knitted wire mesh products to meet the diverse needs of its customers. Whether it's standard mesh configurations or custom-designed solutions, {Company} has the expertise and capabilities to deliver high-quality products that are tailored to specific requirements. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, {Company} is committed to providing innovative and reliable solutions that exceed customer expectations.

Furthermore, {Company} takes pride in its dedication to quality and customer satisfaction. All knitted wire mesh products undergo rigorous testing and quality assurance measures to ensure they meet the highest standards of performance and reliability. With a focus on continuous improvement and innovation, {Company} strives to stay at the forefront of technological advancements in knitted wire mesh manufacturing and application.

As a global leader in knitted wire mesh solutions, {Company} has built a strong reputation for excellence and reliability. Its products are trusted by a diverse customer base across industries such as energy, petrochemical, pharmaceutical, and food processing. With a commitment to delivering superior products and unmatched customer service, {Company} continues to be a preferred partner for those seeking high-quality knitted wire mesh solutions.

In conclusion, knitted wire mesh is a versatile and high-performance material that offers a wide range of benefits for various applications. With {Company} as a trusted source for top-quality knitted wire mesh products, customers can be assured of reliable solutions that meet their specific needs. Whether it's for filtration, sealing, demisting, or any other application, {Company} is dedicated to providing innovative and effective knitted wire mesh solutions that drive success for its customers.

Company News & Blog

Steel Bar Grating: The Latest Update on Durable Metal Grid Structures

**Title: Steel Bar Grating: Revolutionizing Industrial Safety and Infrastructure Development****Introduction**As industries continue to advance, ensuring safety and robust infrastructure becomes paramount. Steel Bar Grating, an innovative product offered by several renowned companies in the market, has become an essential component in various sectors. Its exceptional strength, durability, and versatility make it an ideal choice for industrial platforms, walkways, stair treads, and countless other applications. This article explores the extraordinary features and potential applications of Steel Bar Grating, while emphasizing its importance in maintaining a safe and efficient working environment.**Unmatched Strength and Durability**Steel Bar Grating is made of high-quality carbon steel or stainless steel bars, meticulously welded at intersecting points to create a grid-like structure. This diligent construction technique ensures exceptional strength, enabling the grating to withstand heavy loads, impact, and various environmental factors. It offers greater load-bearing capacity compared to other materials, making it an indispensable element in industries such as manufacturing, petrochemicals, and transportation.Moreover, the high-quality raw materials utilized in the manufacturing process enhance the grating's durability, giving it a longer service life with minimal maintenance requirements. This durability not only saves costs on replacements but also contributes to sustainable infrastructure development.**Versatility in Applications**Steel Bar Grating finds extensive use across multiple industries due to its versatility in applications. Here are some notable areas where this remarkable product exhibits exceptional performance:1. Industrial Platforms: Steel Bar Grating provides a secure and non-slip working surface for workers who operate on elevated platforms and catwalks. Its open design allows debris and wastewater to pass through, reducing the risk of accidents caused by slippery surfaces.2. Walkways and Stair Treads: In commercial and industrial buildings, Steel Bar Grating is an ideal material for walkways and stair treads. Its sturdy structure ensures safe pedestrian movement while its open design prevents the accumulation of liquids and debris.3. Drainage Solutions: The grating's open surface design enables efficient drainage, making it a reliable choice for industries where water management is crucial. It facilitates the movement of wastewater, preventing the formation of stagnant pools and improving the overall hygiene and safety of the facility.4. Shelving and Racks: Steel Bar Grating forms robust shelves and racks, providing an efficient storage solution for warehouses, manufacturing facilities, and logistics centers. The grating's strength allows it to support heavy loads, optimizing storage capacity without compromising safety.**Company Introduction: Leader in Innovating Steel Bar Grating Solutions**As a prominent player in the steel grating industry, {} (Company Name) has emerged as a market leader due to its unrivaled commitment to quality and customer satisfaction.With a rich experience spanning over several decades, our company has perfected the art of manufacturing precision-engineered Steel Bar Grating solutions. Our team of skilled professionals utilizes state-of-the-art technology and adheres to rigorous quality control standards to produce grating products that surpass industry benchmarks.We pride ourselves on offering a wide range of grating options, including different bar sizes, spacing, and surface types, to suit the specific requirements of our clients. Our expert engineers work closely with customers to design customized Steel Bar Grating solutions that address their unique needs and ensure optimal performance.In addition to our exceptional product line, we provide comprehensive customer support, prompt delivery, and efficient after-sales services. We believe in fostering long-term partnerships with our clients by consistently meeting their expectations and delivering exceptional value.**Conclusion**Steel Bar Grating has undoubtedly revolutionized industrial safety and infrastructure development, providing sturdy and reliable solutions for various applications. Its unmatched strength, durability, and versatility make it an indispensable choice for industries worldwide. With continued innovation and commitment to excellence, companies like {} (Company Name) are propelling this remarkable product forward, paving the way for safer and more efficient industrial environments.

Top-Rated Galvanized Bar Grating: A Comprehensive Guide and Pricing Information

Galvanized Bar Grating - Durable and ReliableBar grating is a type of steel grating that is made of welded or pressure-locked bar-shaped bearing bars and crossbars with a certain distance. It is a popular and affordable choice for industrial, commercial, and residential applications, where strength, durability, and safety are required. Galvanized bar grating, in particular, is one of the most common types of steel bar grating used today. It offers enhanced corrosion resistance, longevity, and aesthetic appeal, making it an ideal choice for both indoor and outdoor environments.Galvanized bar grating is made by dipping the steel bars and crossbars into a hot-dip galvanizing bath, which coats them with a layer of zinc. The zinc coating serves as a protective layer against rust, corrosion, and other forms of environmental damage. This allows galvanized bar grating to last longer and provides protection against damage caused by water, chemicals, and harsh weather conditions. Moreover, the zinc coating provides a shiny and professional look that can enhance the aesthetic appeal of any structure.Galvanized Bar Grating ApplicationsGalvanized bar grating is commonly used in industrial and commercial applications, such as walkways, catwalks, platforms, stairs, and ramps. It is also used as safety grating for fencing, decking, and air ventilation systems. In addition, galvanized bar grating can be used for decorative purposes, such as architectural grilles, sunscreens, and façade cladding.Galvanized bar grating is a versatile material that can be customized to fit your specific needs. It can be cut to size, welded, or fabricated to create different shapes and configurations. Its strength, durability, and flexibility make it an ideal material for challenging environments and heavy-duty applications.Why Choose Galvanized Bar Grating?Galvanized bar grating is a great choice for many reasons, including:Enhanced durability and longevity. The zinc coating on galvanized bar grating provides protection against corrosion, rust, and other forms of environmental damage. This allows the grating to last longer and requires less maintenance.Improved safety and security. Galvanized bar grating offers slip-resistant features that prevent accidents and injuries. It also provides better visibility, which enhances safety in low-light settings.Affordability and value. Galvanized bar grating is a cost-effective solution that offers long-term value. It is easy to install and requires minimal maintenance, which saves time and money.Aesthetic appeal. Galvanized bar grating provides a shiny and professional look that can enhance the appearance of any structure. It is available in a variety of sizes, shapes, and patterns to suit different design needs.Company IntroductionOur company has been providing high-quality galvanized bar grating for over 20 years. We are a trusted supplier of steel grating products for various industries, such as construction, manufacturing, and transportation. We offer a wide range of galvanized bar grating options, including standard and custom sizes, shapes, and configurations. Our team of experts can assist you in choosing the right type of galvanized bar grating for your specific needs.We are committed to delivering exceptional customer service and quality products. Our galvanized bar grating is made of high-quality materials and meets or exceeds industry standards. We offer timely delivery and competitive pricing, without compromising on quality or durability.In conclusion, galvanized bar grating is a durable and reliable material that offers enhanced corrosion resistance, longevity, and aesthetic appeal. It is a cost-effective solution for industrial, commercial, and residential applications, where strength, durability, and safety are required. Our company provides high-quality galvanized bar grating products and services, ensuring a reliable and long-lasting solution for your needs.

High Quality Steel Grates for Durable Flooring Solutions

Metal Bar Grating For Floor: A Durable and Safe SolutionFloor grating has become an essential component of modern industrial and commercial spaces, providing a highly safe and durable surface for workers and equipment. Metal bar grating for floor, also commonly known as steel grating or expanded metal grating, has become a popular choice for many industries due to its high strength and durability.Metal bar grating for floor is made by welding or interlocking steel bars or strips to create a rigid grid-like structure. This structure provides a non-slip surface that can withstand high loads and heavy foot traffic. The gaps between the bars allow for easy drainage, making it suitable for wet and oily environments.Benefits of Metal Bar Grating for FloorDurability:One of the main advantages of metal bar grating for floor is its durability. It is capable of withstanding heavy loads and foot traffic, making it suitable for industrial and commercial applications. The rugged construction ensures that it can withstand harsh environments, including exposure to chemicals, extreme temperatures, and weather conditions.Safety:Metal bar grating for floor provides a safe surface for workers to walk on. The non-slip surface prevents slips, trips, and falls, reducing the risk of workplace accidents and injuries. The open design of the grating allows for easy drainage, reducing the risk of slips and falls caused by wet or oily surfaces.Easy Installation:Metal bar grating for floor is easy to install. It can be custom made to fit any space, and installation is quick and straightforward. The lightweight and modular design make it easy to handle and move around, reducing installation time and costs.Low Maintenance:Metal bar grating for floor requires low maintenance, making it an economical choice for commercial and industrial spaces. The open design allows for easy cleaning and prevents the buildup of debris, reducing the risk of corrosion and rust.Versatility:Metal bar grating for floor is available in a wide range of sizes, materials, and finishes, making it suitable for various applications. It can be fabricated to fit any space and customized to meet specific requirements.Applications of Metal Bar Grating for FloorMetal bar grating for floor is used in various applications across many industries. Some of the popular applications include:- Industrial Walkways: Metal bar grating for floor is commonly used in industrial walkways to provide a non-slip and durable surface.- Flooring: It is a suitable flooring solution for commercial and industrial spaces, including factories, warehouses, and garages.- Drainage: The open design of the grating allows for easy drainage, making it suitable for areas with high levels of water, such as swimming pools and airports.- Stair Treads: Metal bar grating for floor is a safe and durable solution for stair treads and landings.ConclusionMetal bar grating for floor provides a practical, safe, and durable solution for a variety of industrial and commercial applications. The non-slip surface, high strength, and rugged construction make it an ideal choice for areas that require a safe and durable surface. With its versatility and easy installation, metal bar grating for floor is an economical and reliable choice for modern spaces.

Gabion Baskets Used for Constructing Access Track Along Train Station

and Industrial Development. Gabion Retaining Walls: A Sustainable Solution for Industrial DevelopmentIn today's world, sustainable development has become the key focus of various industries. Among the many sustainable solutions, gabion retaining walls have gained immense popularity. These walls are being used in various construction projects, including the construction of access tracks and retaining site boundaries in industrial developments.A gabion retaining wall is a structure that consists of rectangular wire baskets known as gabions. These baskets are filled with rocks and other related materials to form a retaining wall. Gabion retaining walls are highly durable, strong, and resistant to natural elements such as water, wind, and earth pressure.In recent times, gabion retaining walls have been used to retain the site boundary along the length of a new access road to a new industrial development. The use of gabion retaining walls as a boundary wall for site retention is a significant development in sustainable construction.Gabion retaining walls are an eco-friendly solution, using recycled materials that are cost-effective and sustainable. This rock-filled wall system provides an excellent drainage solution and enhances the site's aesthetic appeal by blending naturally into the environment.The industrial development sector is growing rapidly, and there is an urgent need for environmentally responsible construction solutions. Gabion retaining walls have emerged as a sustainable option, addressing the concerns of soil erosion, vegetation displacement, and other environmental issues.Gabion retaining walls are not only sustainable but also offer other benefits, such as flexibility in design, lower maintenance costs, and ease of construction. This wall system is also effective in reducing noise pollution and improving air quality.In conclusion, gabion retaining walls are a practical and eco-friendly solution for industrial development. Their versatility in design and their cost-effectiveness make them a preferred choice for site retention and access road construction. Their sustainable nature is an added advantage, ensuring the long-term durability of these structures. It is time for industries to embrace sustainable construction solutions and mitigate the environmental impact of construction projects.

All You Need to Know About Welded Wire Mesh

Title: Groundbreaking Welded Wire Mesh Innovations Revolutionize the Construction IndustryIntroduction:In recent years, the construction industry has witnessed stunning advancements in materials and technologies, leading to improvements in safety, efficiency, and overall project quality. One notable innovation that has been gaining significant attention is Welded Wire Mesh. Companies around the globe, including (remove brand name), have been introducing game-changing solutions in this field, resulting in a paradigm shift in construction practices. This article will explore the latest advancements in Welded Wire Mesh technology and highlight how they are reshaping the construction industry.The Versatility of Welded Wire Mesh:Welded Wire Mesh serves as a multi-purpose construction material, offering an array of applications in various sectors. The mesh is made up of individual wires welded together to form a strong, durable, and highly flexible structure. Its versatility allows it to be utilized in a wide range of construction projects, including residential, commercial, industrial, and infrastructure developments.Enhanced Structural Integrity:One of the key benefits of Welded Wire Mesh is its ability to enhance the structural integrity of concrete structures. By providing reinforcement, it effectively counters tensile forces, preventing cracks and reducing the risk of structural failures. Moreover, Welded Wire Mesh helps distribute load-bearing capacity across larger areas, resulting in a more stable and secure overall structure.Improved Safety Measures:With safety being a top priority in any construction project, Welded Wire Mesh has emerged as a crucial solution to reinforce concrete foundations, walls, and slabs. The mesh acts as a barrier against potential hazards such as falls, flying debris, and even natural disasters. By incorporating this technology, construction companies can ensure worker safety while delivering high-quality projects.Flexibility in Design and Installation:The flexibility offered by Welded Wire Mesh allows architects and engineers to explore innovative design possibilities while ensuring structural integrity. The mesh can be easily molded and shaped to fit complex geometries, enabling the construction of unique and visually appealing structures. Additionally, its lightweight nature makes transportation and installation hassle-free, reducing overall project time and costs.Sustainability and Environmental Benefits:Welded Wire Mesh is also making strides in promoting sustainable construction practices. By utilizing recycled materials in the manufacturing process, it reduces reliance on virgin resources, leading to a significantly lower carbon footprint. Additionally, the extended lifespan and durability of structures reinforced with Welded Wire Mesh reduce the need for frequent maintenance and repairs, further contributing to environmental sustainability.Market Adoption and Industry Collaborations:As the construction industry recognizes the inherent advantages of Welded Wire Mesh, numerous companies have joined forces to foster innovation and drive the sector forward. Various research institutions and construction conglomerates are investing in research and development initiatives focused on improving Welded Wire Mesh technologies. Collaborations between manufacturers and construction companies are paving the way for groundbreaking advancements, enabling safer, more efficient, and aesthetically pleasing projects.Conclusion:Welded Wire Mesh has emerged as a transformative force within the construction industry, offering numerous benefits ranging from improved structural integrity and safety to enhanced design possibilities and sustainable practices. As companies continue to push the boundaries of innovation, Welded Wire Mesh technology will undoubtedly play a pivotal role in shaping the future of construction. With its versatile applications and continual advancements, construction projects worldwide will see increased efficiency, durability, and overall quality in the coming years.

Understanding the Resistance of 2 Gauge Wire for Electrical Applications

Wires are an essential component of the technological age we live in today. From powering up our homes to transmitting signals across geographical locations, wires have become an indispensable part of our lives. In this article, we will talk about a specific type of wire - 2 AWG or 2 gauge wire. We will learn about its properties, uses, and why it is important. We will also delve into the topic of wire resistance and explain how it works.2 AWG or 2 gauge wire is a type of electrical wire that is commonly used in industrial and commercial applications. This wire is composed of a solid or stranded conductor which is made of copper or aluminum. The term "2 gauge" refers to the thickness of the wire. The higher the gauge number, the thinner the wire is. 2 gauge wire is thicker and therefore can handle more electrical current than thinner wires.One of the key properties of 2 gauge wire is its resistance. The resistance of a wire is the opposition it offers to the flow of electrical current. The resistance of a wire is affected by several factors such as the length of the wire, the cross-sectional area of the wire, and the material of the wire. The wire's resistance can be calculated using the formula R=ρL/A, where R is the resistance, ρ is the resistivity of the material, L is the length of the wire, and A is the cross-sectional area of the wire.The resistance of a wire is an important consideration when selecting a wire for a particular application. Wires that are used in high current applications like power supply circuits must have low resistance to minimize power loss. On the other hand, wires that are used for transmitting signals must have high resistance to prevent signal distortion. 2 gauge wire is commonly used in applications where high current is involved, such as in power transmission and distribution.Another use of 2 gauge wire is in the construction industry. 2 gauge wire is commonly used as binding wire to secure reinforcing bars or rebar in concrete structures. Binding wire is used to hold the rebar in place until the concrete sets. This helps to ensure that the rebar is properly embedded in the concrete and provides the necessary strength to the structure.In conclusion, 2 gauge wire is an essential component in the technological age we live in today. Its properties, such as its resistance, make it ideal for use in high current applications. It is also widely used in the construction industry as binding wire. When selecting a wire for a particular application, it is important to consider its resistance and other factors to ensure that it performs optimally. With the right wire selected, you can be sure that your application will function smoothly and effectively.

New Aluminum Fencing Option: Chain Link Fence with Privacy Slats

Title: Advanced Security Solution Provider Introduces Innovative Fencing TechnologyIntroduction:In the ever-evolving landscape of security solutions, one company is revolutionizing the industry with their pioneering approach. Combining cutting-edge technology with their expertise in perimeter security, this renowned provider is introducing an advanced fencing system that ensures maximum protection. By leveraging their state-of-the-art technology, this company is setting new standards in security infrastructure.Innovative Fencing Solution:With a deep understanding of the evolving security challenges faced by various industries, this market-leading company has developed an innovative fencing solution. This next-generation system, known as an 'Advanced Security Barrier' -- designed to replace conventional chain link fences -- incorporates advanced materials and intelligent features to provide unparalleled protection.Enhanced Durability:The company's new fencing system is constructed using high-grade materials that are highly resistant to wear and tear, weather conditions, and tampering. With durability at the forefront, this advanced security barrier surpasses traditional chain link fences in strength and longevity, providing clients with long-term protection and peace of mind.Intelligent Sensors and Alert Systems:To further fortify its security capabilities, this advanced fencing system incorporates intelligent sensors and alert systems. These state-of-the-art sensors are strategically placed throughout the fence and detect any unauthorized intrusion or tampering. Once triggered, real-time alerts are immediately sent to the security personnel, enabling them to swiftly respond to potential threats.Integration with Integrated Security Systems:One of the standout features of this advanced system is its seamless integration with existing or newly implemented integrated security systems. By synchronizing with other security components like surveillance cameras, access control systems, and intrusion detection systems, this advanced fencing solution creates a comprehensive and cohesive security infrastructure. Such integration enables swift and effective response measures in the event of a security breach, ensuring the safety of both people and assets on-site.Customization Options:Understanding that different industries and organizations have unique security requirements, this company offers a wide range of customization options, tailoring the advanced fencing system to meet specific needs. Clients have the flexibility to choose various fence heights, materials, and colors to match their surroundings, while maintaining the highest level of security.Applications across Industries:The versatility of this innovative fencing solution makes it suitable for a diverse range of industries. From critical infrastructure facilities, government premises, and military installations to educational institutions, commercial establishments, and residential communities, the advanced security barrier provides reliable protection in any setting.Unmatched Expertise and Reliability:Backed by years of experience and a commitment to excellence, this company prides itself on providing unmatched expertise and reliability. With a team of highly skilled professionals, they work closely with clients to understand their unique security challenges, offering tailored solutions that meet their specific requirements. From the initial design phase to installation and post-sales support, this dedicated team ensures a seamless experience for their clients.Conclusion:With its revolutionary advanced fencing solution, this renowned security provider is changing the landscape of perimeter security. By combining cutting-edge technology, durable materials, and intelligent features, they have created a system that offers unmatched protection, seamlessly integrated with existing security infrastructure. With their commitment to excellence and acclaimed reliability, this company continues to meet the evolving security needs of various industries, setting new standards in advanced security solutions.

Discover the Benefits of Knitted Wire Mesh for Various Applications

Knitted Wire Mesh: A High-Quality Solution for Various Applications{Company} is a leading provider of knitted wire mesh, a versatile and high-quality material that is used in a wide range of applications across various industries. With years of experience and expertise in the field, {Company} has established itself as a trusted source for knitted wire mesh products that meet the highest standards of quality and performance.Knitted wire mesh is a type of wire fabric that is produced by knitting or looping wires together. This unique construction gives the mesh its flexibility and durability, making it ideal for applications where strength and resilience are crucial. The mesh can be manufactured from different materials, including stainless steel, copper, and aluminum, each offering its own set of properties and advantages.One of the key benefits of knitted wire mesh is its ability to provide excellent filtration and separation capabilities. The interlocking wire loops create a uniform and consistent mesh structure that is highly effective in capturing and retaining solid particles, liquids, and gases. This makes knitted wire mesh an ideal choice for applications such as filtration, separation, and straining in industries such as automotive, aerospace, and chemical processing.In addition to its filtration capabilities, knitted wire mesh is also widely used for its excellent sealing and gasketing properties. The flexible and compressible nature of the mesh allows it to conform to irregular surfaces and provide a tight seal, making it suitable for applications such as gaskets, seals, and packing materials in industrial equipment and machinery.Another important application of knitted wire mesh is in the field of demisting and mist elimination. The mesh is highly efficient in capturing and removing liquid droplets from gas streams, making it a critical component in processes such as air and gas purification, chemical processing, and environmental control.{Company} offers a wide range of knitted wire mesh products to meet the diverse needs of its customers. Whether it's standard mesh configurations or custom-designed solutions, {Company} has the expertise and capabilities to deliver high-quality products that are tailored to specific requirements. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, {Company} is committed to providing innovative and reliable solutions that exceed customer expectations.Furthermore, {Company} takes pride in its dedication to quality and customer satisfaction. All knitted wire mesh products undergo rigorous testing and quality assurance measures to ensure they meet the highest standards of performance and reliability. With a focus on continuous improvement and innovation, {Company} strives to stay at the forefront of technological advancements in knitted wire mesh manufacturing and application.As a global leader in knitted wire mesh solutions, {Company} has built a strong reputation for excellence and reliability. Its products are trusted by a diverse customer base across industries such as energy, petrochemical, pharmaceutical, and food processing. With a commitment to delivering superior products and unmatched customer service, {Company} continues to be a preferred partner for those seeking high-quality knitted wire mesh solutions.In conclusion, knitted wire mesh is a versatile and high-performance material that offers a wide range of benefits for various applications. With {Company} as a trusted source for top-quality knitted wire mesh products, customers can be assured of reliable solutions that meet their specific needs. Whether it's for filtration, sealing, demisting, or any other application, {Company} is dedicated to providing innovative and effective knitted wire mesh solutions that drive success for its customers.

Wire Bending: The Complete Guide to Binding Wire for Various Applications

[Company Name], a Leading Provider of High-Quality Bindling Wire, Revolutionizes the Industry with Innovative Solutions[CITY, DATE] - [Company Name], a renowned industry leader, has made significant strides in revolutionizing the bindling wire market. With a strong commitment to providing customers with high-quality products, the company has introduced innovative solutions that have reshaped the industry landscape.Bindling wire, also known as baling wire, plays a crucial role in a wide range of industries, including agriculture, construction, and packaging. It is widely used for securing and binding various materials, making it an essential component for businesses worldwide. Recognizing the importance of this product, [Company Name] has focused its efforts on creating solutions that exceed industry standards in terms of performance and reliability.Since its inception, [Company Name] has been dedicated to delivering superior bindling wire products through continuous research and development. With an unwavering commitment to innovation, the company has established itself as a trusted partner for businesses seeking secure and efficient binding solutions."Our mission is to provide our customers with the highest quality bindling wire products that are not only reliable but also cost-effective," said [Company Name] CEO. "Through leveraging cutting-edge technology and implementing rigorous quality control measures, we strive to meet and exceed our customer's expectations."One of the key aspects that sets [Company Name] apart is its state-of-the-art manufacturing process. By leveraging advanced machinery and employing highly skilled technicians, the company ensures that every bindling wire produced adheres to the highest standards of quality. This commitment to excellence has earned [Company Name] a reputation for providing durable and dependable products that withstand even the most demanding applications.Furthermore, [Company Name] has invested heavily in research and development to address common challenges faced by businesses when using bindling wire. Thorough market analysis and customer feedback have allowed the company to identify and tackle issues such as wire breakage, weak tensile strength, and difficult application processes. As a result, [Company Name] has developed innovative bindling wire alternatives that offer enhanced performance and durability.One notable solution introduced by [Company Name] is a revolutionary type of bindling wire that boasts improved tensile strength and flexibility. This product eliminates the need for multiple wire strands, reducing the risk of breakage and increasing overall efficiency. Additionally, the company has developed specialized coatings that provide corrosion resistance, enabling the wire to withstand harsh environmental conditions.In line with the growing demand for sustainable products, [Company Name] also emphasizes the use of eco-friendly materials and production methods. By incorporating recycled materials into their wire manufacturing process, the company contributes to the reduction of waste and environmental impact.A key factor contributing to [Company Name]'s success is its unwavering commitment to customer satisfaction. The company offers exceptional customer service, ensuring that clients receive personalized attention and timely support. Additionally, [Company Name] provides comprehensive product training and technical assistance, helping users optimize the performance of their bindling wire.As an industry leader, [Company Name] actively participates in various industry events, exhibitions, and conferences to showcase its latest innovations and connect with potential customers and partners. Such engagements allow the company to gain valuable insights into evolving market trends and foster collaboration within the industry.Looking ahead, [Company Name] aims to continue transforming the bindling wire market through continuous innovation and exceptional customer service. By staying at the forefront of technological advancements and maintaining focus on customer satisfaction, [Company Name] remains poised to lead the industry for years to come.About [Company Name]:[Company Name] is a renowned provider of high-quality bindling wire solutions, catering to diverse industries worldwide. Through its commitment to innovation, the company develops cutting-edge products that exceed customer expectations. With a focus on quality, sustainability, and customer satisfaction, [Company Name] has established itself as an industry leader in the bindling wire market.For more information, please visit [Company Website].