Durable Copper Wire Mesh for Various Applications

By:Admin

Established in [year], [Company Name] has quickly risen to prominence in the copper wire mesh industry. With their state-of-the-art manufacturing facilities and a team of skilled professionals, they have been able to develop a wide range of copper wire mesh products that cater to the diverse needs of their clientele. The company prides itself on its ability to produce custom-made solutions that meet the specific requirements of their customers.

One of the key factors that sets [Company Name] apart from its competitors is its focus on quality. They have implemented stringent quality control measures at every stage of the manufacturing process to ensure that their products meet the highest standards. By using only the finest grade of copper wire, [Company Name] is able to produce copper wire mesh products that are exceptionally durable and resistant to corrosion, making them suitable for use in even the most demanding environments.

Furthermore, [Company Name] is dedicated to innovation and continuously invests in research and development to improve their products. This commitment to innovation has allowed them to stay ahead of market trends and provide cutting-edge solutions to their customers. As a result, they have been able to expand their product line to include an extensive range of copper wire mesh products that are designed to meet the evolving needs of various industries.

In addition to their focus on quality and innovation, [Company Name] places a strong emphasis on customer satisfaction. They understand that every customer has unique requirements, and they go the extra mile to ensure that their products are tailored to meet these needs. With a team of knowledgeable and attentive customer service representatives, [Company Name] is able to provide expert guidance to their customers, helping them choose the most suitable copper wire mesh products for their applications.

As part of their commitment to sustainability, [Company Name] also places a strong emphasis on environmental responsibility. They have implemented eco-friendly manufacturing practices, such as the use of recyclable materials and energy-efficient processes, to minimize their impact on the environment. This dedication to sustainability has resonated with environmentally conscious customers who are looking for reliable and environmentally friendly copper wire mesh solutions.

Looking to the future, [Company Name] has ambitious plans for growth and expansion. They are continuously seeking new opportunities to broaden their market reach and serve a wider customer base. By leveraging their expertise and resources, [Company Name] is poised to further solidify its position as a leading provider of copper wire mesh products in the industry.

In conclusion, [Company Name] has established itself as a reputable and reliable supplier of copper wire mesh products. With a steadfast commitment to quality, innovation, customer satisfaction, and environmental responsibility, they have proven themselves to be a valuable partner for businesses in need of high-quality copper wire mesh solutions. As they continue to grow and evolve, [Company Name] is set to remain at the forefront of the copper wire mesh industry, shaping the future of the market with their superior products and services.

Company News & Blog

Durable Welded Wire Fence for Your Property - Find Quality Options Here

Welded Wire Fence: The Perfect Solution for Security and SafetyIn today's world, security and safety are of utmost importance. Whether it's protecting a commercial property, securing a residential area, or keeping livestock safe on a farm, a reliable fencing solution is essential. This is where Welded Wire Fence comes into play. With its durable construction and versatile applications, it is the perfect solution for a wide range of security and safety needs.Welded Wire Fence is made from high-quality steel wire that is welded together to create a strong and secure mesh pattern. This construction provides a level of strength and stability that is unmatched by other types of fencing. It is resistant to corrosion and rust, making it suitable for outdoor use in various weather conditions. The fence is also available in a variety of heights and mesh sizes, making it customizable to suit specific security needs.One of the primary advantages of Welded Wire Fence is its versatility. It can be used for a wide range of applications, including perimeter fencing for commercial and industrial properties, boundary fencing for residential areas, and containment fencing for livestock and agricultural purposes. Its ability to adapt to different needs makes it a popular choice for many customers.In addition to its strength and versatility, Welded Wire Fence is also easy to install and maintain. The panels can be easily attached to posts or existing structures, providing a quick and efficient installation process. Once in place, the fence requires minimal maintenance, saving time and money for the property owner.To meet the growing demand for fencing solutions, {Company Name} has been at the forefront of providing high-quality Welded Wire Fence products to customers. With years of experience in the industry, {Company Name} has established itself as a trusted supplier of fencing solutions, offering a wide range of options to meet varying customer needs.{Company Name}'s Welded Wire Fence products are manufactured to the highest standards, ensuring that customers receive a reliable and durable fencing solution. The company takes pride in its commitment to quality, using only the best materials and advanced manufacturing techniques to produce fencing products that meet and exceed industry standards.As a customer-focused company, {Company Name} works closely with each client to understand their specific requirements and provide tailored solutions. Whether it's a large-scale commercial project or a small residential installation, {Company Name} has the expertise and resources to deliver high-quality Welded Wire Fence products that meet customer expectations.In addition to providing top-quality products, {Company Name} also offers excellent customer service and support. From the initial inquiry to the final installation, the company's team of experts is dedicated to assisting customers every step of the way. This commitment to customer satisfaction has helped {Company Name} build a strong reputation in the industry.In conclusion, Welded Wire Fence is a durable, versatile, and reliable fencing solution that offers the perfect combination of security and safety. With its strength, versatility, and ease of installation and maintenance, it is the ideal choice for a wide range of applications. {Company Name} has been a leading provider of Welded Wire Fence products, offering high-quality solutions and exceptional customer service. For anyone in need of a dependable fencing solution, {Company Name} is the go-to source for all Welded Wire Fence needs.

High-Quality Galvanized Bar Grating: The Ultimate Guide

Global Grating (Brand Name Removed), a renowned manufacturer of high-quality steel grating products, has recently introduced a new line of galvanized bar grating to its extensive range of products. The company, with its commitment to superior quality and innovation, aims to cater to the growing demand for durable and reliable grating solutions across various industries.Galvanized bar grating is a type of grating that is manufactured from carbon steel and then hot-dip galvanized to provide corrosion resistance. This process involves immersing the steel grating in a bath of molten zinc, which creates a protective layer on the surface of the grating, ensuring long-term durability and resistance to the elements.With the introduction of galvanized bar grating, Global Grating (Brand Name Removed) aims to provide its customers with a superior grating solution that is suitable for outdoor applications, industrial environments, and areas where corrosion resistance is essential. The galvanized finish not only adds to the aesthetic appeal of the grating but also enhances its longevity, making it a cost-effective and reliable option for a wide range of applications.In addition to the galvanized finish, Global Grating (Brand Name Removed) ensures that its bar grating products are manufactured to the highest standards, with a focus on quality, precision, and durability. The company utilizes advanced manufacturing processes and state-of-the-art technology to produce grating solutions that meet the most stringent industry requirements.Global Grating (Brand Name Removed) takes pride in its ability to customize galvanized bar grating to meet the specific needs of its customers. Whether it is a unique bar spacing, surface finish, or load-bearing capacity, the company works closely with its clients to deliver tailored grating solutions that meet their exact specifications.The versatility of galvanized bar grating makes it an ideal choice for a wide range of applications, including industrial walkways, platforms, stair treads, catwalks, and trench covers. The high strength-to-weight ratio of steel grating, combined with the corrosion-resistant properties of the galvanized finish, makes it a practical and reliable solution for both indoor and outdoor use.Global Grating (Brand Name Removed) emphasizes the importance of sustainability in its manufacturing processes, and the introduction of galvanized bar grating aligns with its commitment to environmentally responsible practices. The long lifespan and low maintenance requirements of galvanized steel grating make it a sustainable choice for businesses looking to minimize their environmental impact while ensuring high-quality infrastructure solutions.With its extensive experience and expertise in the grating industry, Global Grating (Brand Name Removed) continues to set the benchmark for reliable and innovative grating solutions. The company's dedication to superior quality, exceptional customer service, and continuous improvement has established it as a trusted provider of grating products to a diverse range of industries worldwide.Global Grating (Brand Name Removed) remains at the forefront of the grating industry, constantly exploring new technologies and materials to enhance its product offerings and meet the evolving needs of its customers. The introduction of galvanized bar grating is a testament to the company's commitment to innovation and its ability to deliver cutting-edge solutions that exceed industry expectations.As the demand for high-quality, durable, and sustainable grating solutions continues to grow, Global Grating (Brand Name Removed) aims to remain a reliable partner for businesses seeking reliable infrastructure products. The introduction of galvanized bar grating further solidifies the company's position as a leader in the grating industry, providing customers with unmatched value, performance, and longevity in their infrastructure investments.

Need Wire Mesh? Call Today for Quality Supplies!

Wire Mesh: A Guide to Choosing the Right MaterialWire mesh is a versatile material that finds its way into many applications. From filtration screens to safety barriers, wire mesh serves many purposes and can be made from a range of materials. One of the most popular materials for wire mesh is stainless steel.Stainless steel mesh is a durable and corrosion-resistant option that is perfect for outdoor applications or dealing with harsh chemicals. It is a popular material for construction and architectural purposes as well. Here's a closer look at stainless steel mesh and how to choose the right material for your project.Types of Stainless Steel MeshThere are two primary types of stainless steel mesh: woven and welded. Woven wire mesh is made by weaving wires together in a pattern to create a sheet of mesh. Welded wire mesh is created by spot-welding wires at each intersection to create a sheet of mesh. Each type of mesh has different characteristics and is suited for different applications.Woven stainless steel mesh is generally more flexible than welded mesh, making it an ideal option for applications that require flexing or bending. However, it is often more expensive than welded mesh. Welded stainless steel mesh is typically less expensive than woven mesh, and it is often stronger and more rigid.Choosing the Right SizeStainless steel mesh comes in a variety of sizes, commonly measured in mesh count per inch. The higher the mesh count, the finer the mesh. The size of the mesh is important to consider based on the application, as it affects the flow of air or liquid through the mesh.For example, a 60 mesh count would be appropriate for a window screen, while a 400 mesh count would be more suitable for a filtration screen. Be sure to consult with a supplier to ensure you choose the right size for your specific application.Choosing the Right Grade of Stainless SteelStainless steel is available in various grades, each with its own properties. The most common grades for stainless steel wire mesh are 304, 316, and 316L.- Grade 304 is a common general-purpose stainless steel that is used in a variety of applications. It has good corrosion resistance, high-temperature performance, and is suitable for most applications.- Grade 316 is an austenitic stainless steel with superior corrosion resistance and is ideal for applications exposed to harsh chemicals and high temperatures.- Grade 316L is a low carbon version of grade 316 that provides even greater corrosion resistance, making it ideal for applications in marine environments or chemical processing plants.When selecting the grade of stainless steel, consider the environmental conditions, such as temperature, humidity, and exposure to chemicals. This will help you choose the appropriate grade for your application.ConclusionStainless steel mesh is a versatile and durable material that can be used in various applications. By selecting the right type of mesh, size, and grade of stainless steel, you can ensure that your wire mesh performs optimally and lasts longer. To learn more about wire mesh and other options available, contact a reputable supplier.

Top-quality Concertina, Razor, and Barbed Wire available from Manufacturers in Kolkata, India

, Razor Wire, Barbed Wire, Manufacturers, Suppliers, Wholesale, Kolkata, IndiaIn today's world of heightened security concerns, people are increasingly looking for ways to secure their properties. This is where the usefulness of concertina wire, razor wire, and barbed wire comes into play. These types of wire have been used for decades to prevent intruders from accessing properties, and they continue to be popular options today.If you are looking for high-quality concertina wire, razor wire, or barbed wire, then you need to contact reliable manufacturers and suppliers. In Kolkata, India, Om Wire and Wire are renowned manufacturers, suppliers, and wholesalers of these types of wire.Concertina WireConcertina wire is a type of razor wire that is manufactured by twisting two strands of wire together to create a spiraling effect. The wire is then formed into coils, which can be used for fencing and other security applications.One of the main advantages of concertina wire is that it is highly effective at deterring intruders. The sharp spikes on the wire make it difficult for anyone to climb over the fence or wall that it surrounds. Additionally, the wire is designed to unravel and expand, making it an effective barrier against even the most determined intruders.Razor WireRazor wire is similar to concertina wire in that it also consists of sharp, twisted wires that are formed into coils. However, razor wire is usually made from thicker and more durable materials than concertina wire. This makes it a more effective deterrent against intruders.Razor wire is commonly used for security fencing and is often installed on walls, fences, and gates. In addition to deterring intruders, it also serves as a visual warning that the property is secured and not to be crossed.Barbed WireBarbed wire is a type of wire that has sharp points on it, and is used for fencing and other security applications. It consists of two or more strands of wire that are twisted together, with sharp barbs placed at regular intervals.Barbed wire is typically less expensive than other types of wire, and is often used for temporary fencing or in rural areas to prevent animals from entering crops or grazing fields.However, barbed wire can also be used for security applications. When installed on top of walls or fences, the sharp barbs make it difficult for anyone to climb over or gain access to the property.ConclusionIf you are in need of concertina wire, razor wire, or barbed wire, then you need to contact reliable manufacturers and suppliers. Om Wire and Wire are renowned manufacturers, suppliers, and wholesalers of these types of wire in Kolkata, India.By installing concertina wire, razor wire, or barbed wire on your property, you can significantly increase its security and prevent intruders from accessing your premises. These types of wire are highly effective and are widely used around the world for security purposes. Contact Om Wire and Wire today to learn more about their range of wire products and how they can help you secure your property.

High-Quality Copper Wire Mesh: The Latest News and Updates

Copper wire mesh is gaining popularity in various industrial and commercial applications due to its durability, versatility, and excellent conductivity. This type of mesh is made by weaving copper wires together to create a strong and flexible material that can be used for a wide range of applications.One company that has been at the forefront of producing high-quality copper wire mesh is {}. With a history dating back to 1998, they have established themselves as a leading manufacturer and supplier of wire mesh products, including copper wire mesh. Their commitment to producing top-quality materials and their dedication to customer satisfaction have earned them a stellar reputation in the industry.The copper wire mesh produced by {} is known for its high tensile strength and resistance to corrosion, making it ideal for use in demanding environments. It is commonly used in filtration, sieving, and screening applications across a variety of industries, including mining, agriculture, and construction. In addition, copper wire mesh is also used in various artistic and decorative applications due to its attractive appearance and malleability.One of the key advantages of copper wire mesh is its excellent conductivity, which makes it highly suitable for use in electrical and electronic applications. This property allows for the efficient transmission of electrical signals and ensures reliable performance in demanding environments. As a result, copper wire mesh is often used in the manufacturing of electrical components, electromagnetic shielding, and grounding applications.In addition to its functional properties, copper wire mesh is also known for its aesthetic appeal. The distinctive reddish-brown color of copper adds a unique visual element to architectural and interior design applications. Copper wire mesh can be used in decorative screens, room dividers, and facades to create a striking visual impact in commercial and residential settings.With the increasing demand for sustainable and eco-friendly materials, copper wire mesh has emerged as a popular choice for environmentally conscious consumers. Copper is a fully recyclable material, making it a sustainable option for various applications. Furthermore, copper wire mesh is naturally resistant to bacteria, fungi, and other microorganisms, making it a hygienic choice for food processing and medical applications.The team at {} takes great pride in their ability to customize copper wire mesh to meet the specific requirements of their customers. They offer a wide range of mesh sizes and wire diameters, as well as custom weaving patterns to ensure that their products meet the unique needs of each client. Additionally, their state-of-the-art manufacturing facilities and quality control processes ensure that every batch of copper wire mesh meets the highest standards of excellence.As the demand for copper wire mesh continues to grow across various industries, {} is poised to meet the needs of their customers with innovative solutions and superior quality products. With a strong commitment to continuous improvement and customer satisfaction, they are well-positioned to remain a leader in the production and supply of copper wire mesh for years to come.In conclusion, copper wire mesh has become a versatile and widely used material in numerous industrial and commercial applications. With its exceptional conductivity, durability, and aesthetic appeal, it is no wonder that copper wire mesh has become a preferred choice for a wide range of applications. As a leading manufacturer and supplier of wire mesh products, {} is dedicated to providing top-quality copper wire mesh that meets the unique needs of their customers. Their commitment to excellence and customer satisfaction makes them a trusted partner for businesses seeking reliable and high-performance wire mesh solutions.

Durable and Versatile Welded Wire Mesh: The Perfect Solution for Your Projects

Welded Wire Mesh Market is Expected to Witness a CAGR of X% By 2025The global welded wire mesh market is expected to witness significant growth in the coming years, with a projected CAGR of X% from 2020 to 2025. The market is being driven by increasing demand from various end-use industries such as construction, agriculture, transportation, and industrial sectors.Welded wire mesh, also known as welded wire fabric, is a mesh product that is made by welding individual wires together to form a grid. It is commonly used in concrete reinforcement, fencing, animal cages, and various other applications. The product is known for its strength, durability, and cost-effectiveness, which has contributed to its widespread use in different industries.One of the key players in the global welded wire mesh market is {}, a leading manufacturer and supplier of welded wire mesh products. With a strong market presence and a wide range of offerings, the company has been contributing to the growth of the market by providing high-quality products to its customers.Established in [year], {} has earned a reputation for excellence in the industry. The company's state-of-the-art manufacturing facilities are equipped with advanced technology and machinery, allowing them to produce a wide variety of welded wire mesh products to meet the diverse needs of their customers. From standard wire mesh sheets to custom-made products, {} is committed to delivering top-notch solutions to its clients.In addition to manufacturing, {} also focuses on research and development to continuously improve the quality and performance of its products. By investing in innovation and technology, the company has been able to stay ahead of the competition and keep up with the ever-changing market demands.Furthermore, {} has a strong distribution network that enables them to reach customers in various regions around the world. Their products are well-received in the global market, and their commitment to customer satisfaction has earned them a loyal clientele.The growth of the global welded wire mesh market can also be attributed to the increasing demand from the construction industry. With the rising urbanization and infrastructure development projects in emerging economies, there is a growing need for high-quality construction materials such as welded wire mesh. The product is used in various construction applications, including concrete reinforcement, wall and floor systems, and precast elements, driving its demand in the market.Moreover, the agricultural sector is another significant end-user of welded wire mesh. The product is widely used in fencing, animal enclosures, and crop protection, contributing to its demand from the agricultural industry. As agriculture continues to mechanize and modernize, the market for welded wire mesh is expected to witness further growth.The transportation and industrial sectors also contribute to the demand for welded wire mesh products. Applications such as security fencing, machine guards, and material handling equipment utilize welded wire mesh, creating opportunities for market growth in these sectors.Overall, the global welded wire mesh market is poised for significant expansion in the coming years, driven by the increasing demand from various end-use industries. With companies like {} leading the way in manufacturing and supplying high-quality products, the market is expected to witness steady growth and development. As technological advancements continue to enhance the product's performance and versatility, the prospects for the welded wire mesh market look promising.

Discover the Versatility and Durability of Stainless Steel Mesh

Title: Advanced Stainless Steel Mesh: A Revolutionary Solution for Various IndustriesIntroduction:In today's world, the demand for high-quality, durable, and versatile materials is skyrocketing across numerous industries. Addressing this need, an innovative company has emerged with a ground-breaking product – Stainless Steel Mesh (brand name omitted). This advanced stainless steel mesh is poised to revolutionize a myriad of sectors, providing superior strength, corrosion resistance, and endless application possibilities. In this article, we delve into the key features, manufacturing process, and potential industry applications of this cutting-edge material.Key Features:The advanced stainless steel mesh is engineered using state-of-the-art manufacturing techniques, ensuring it possesses an array of indispensable features:1. Unmatched Strength: The stainless steel mesh offers unparalleled tensile strength, making it capable of withstanding extreme pressure, tension, and mechanical stress. Its robust structure ensures longevity and resistance against wear and tear, making it an ideal choice for heavy-duty applications.2. Corrosion Resistance: Stainless steel alloys inherently exhibit remarkable corrosion resistance properties. The stainless steel mesh builds upon this trait, making it highly suitable for applications in harsh environments, where exposure to chemicals, moisture, or fluctuating temperatures may compromise the durability of other materials.3. Flexibility and Versatility: The stainless steel mesh offers immense flexibility, allowing it to be easily molded, shaped, and cut into various sizes and forms. This adaptability makes it a versatile material, suitable for a wide range of industries, including construction, filtration, automotive, aerospace, and manufacturing.4. Enhanced Safety: With a mesh structure that ensures efficient airflow and visibility, the stainless steel mesh finds its application in safety-related sectors, such as architecture, fencing, and protective equipment. It provides an effective barrier while simultaneously allowing unobstructed visibility and air circulation, prioritizing safety without compromising aesthetics.Manufacturing Process:The production of the stainless steel mesh involves a meticulous manufacturing process, combining state-of-the-art technology with experienced craftsmanship to ensure impeccable quality. Starting with high-grade stainless steel alloys, the process involves weaving and interlocking individual wires with precision. The resulting mesh is then subjected to rigorous quality control checks to meet international standards before being made available to various industries.Industry Applications:1. Construction: The stainless steel mesh finds extensive use in the construction industry for reinforcing concrete structures, providing enhanced strength and durability. It is also employed in architecture for creating awe-inspiring facades, balustrades, and functional elements, adding a contemporary touch to modern buildings.2. Filtration: The exceptional corrosion resistance and high tensile strength of the stainless steel mesh make it an optimal material for filtration purposes. It is used in water filtration systems, oil refineries, food processing plants, and other filtration applications where precise separation and longevity are critical.3. Automotive and Aerospace: The stainless steel mesh plays a vital role in the automotive and aerospace sectors, ensuring efficient airflow management, venting, and filtration. It finds applications in engine components, exhaust systems, air filters, and even interior trims, contributing to enhanced performance, safety, and aesthetics.4. Manufacturing and Assembly: The versatility of the stainless steel mesh makes it an invaluable material for manufacturing and assembly processes. It finds applications in conveyor belts, sieves, packaging equipment, machinery guarding, and other automation systems, facilitating smooth and efficient operations.In conclusion, the advanced stainless steel mesh offered by the undisclosed company holds immense potential for numerous industries. With its unrivaled strength, corrosion resistance, flexibility, and versatility, it has the power to reshape the way industries approach construction, filtration, automotive, aerospace, and manufacturing. As technology continues to evolve, this revolutionary material aims to provide solutions that meet the ever-expanding demands of a dynamic world.

High-Quality Steel Bar Grating for Industrial Use

Steel Bar Grating: A Versatile and Durable Solution for Industrial ApplicationsSteel bar grating is a versatile and durable material that is widely used in a variety of industrial applications. It is made from steel bars that are welded, pressure-locked, or riveted together to form a grid-like structure. This design allows for the passage of light, air, heat, and sound, making it ideal for use in flooring, stair treads, platform and catwalks, and other applications where a solid, non-slip surface is needed.One of the leading manufacturers of steel bar grating is {}, a company that has been in the industry for over 30 years. They are known for their commitment to quality and their ability to customize grating solutions to meet the specific needs of their customers. With a wide range of products, including standard welded bar grating, heavy-duty steel grating, aluminum grating, and fiberglass grating, they have become a trusted supplier for clients in industries such as oil and gas, mining, manufacturing, and transportation.The versatility of steel bar grating makes it an excellent choice for a wide range of industrial applications. Its strength and durability make it suitable for heavy-duty use, and its non-slip surface provides a safe working environment for employees. In addition, steel bar grating is resistant to corrosion and can withstand extreme temperatures, making it ideal for use in harsh environments such as chemical plants, food processing facilities, and marine applications.One of the key benefits of steel bar grating is its ability to provide a high level of security without obstructing the flow of light, air, or sound. This makes it an ideal choice for applications where visibility and ventilation are important, such as in outdoor walkways, parking garages, and security fencing. Furthermore, steel bar grating is easy to install and maintain, reducing downtime and lowering overall maintenance costs for industrial facilities.In addition to its practical benefits, steel bar grating is also a sustainable and environmentally friendly material. It is 100% recyclable, and its long lifespan reduces the need for frequent replacements, leading to a reduction in waste and energy consumption. Furthermore, steel bar grating is manufactured using a high percentage of recycled materials, making it an eco-friendly choice for businesses looking to reduce their environmental impact.With {}’s dedication to quality and innovation, they have continued to develop new products and services to meet the evolving needs of their customers. Their in-house engineering team works closely with clients to design customized grating solutions that meet specific requirements, ensuring the highest level of performance and reliability. In addition, they provide a range of value-added services, including cutting, welding, and galvanizing, to deliver turnkey solutions to their customers.As a leading supplier of steel bar grating, {} has established a strong reputation for delivering high-quality products and exceptional customer service. Their commitment to excellence and continuous improvement has earned them the trust of clients in various industries, and their dedication to sustainability and innovation sets them apart in the market. With a focus on providing durable, safe, and environmentally friendly solutions, they continue to be a preferred choice for businesses seeking reliable grating solutions for their industrial applications.

Durable Galvanized Bar Grating for Various Applications

Galvanized Bar Grating: The Superior Choice for Industrial FlooringGalvanized bar grating has emerged as the preferred choice for industrial flooring due to its durability, strength, and corrosion resistance. It is a type of metal grate that is commonly used in industrial settings to allow for the passage of air, light, heat, and sound while providing maximum support and safety for workers and equipment. When it comes to choosing a reliable and long-lasting flooring solution for industrial applications, galvanized bar grating stands out as the superior option.The process of galvanization involves coating the steel grating with a protective layer of zinc, which creates a barrier against corrosion and extends the lifespan of the material. This added layer of protection makes galvanized bar grating ideal for outdoor and harsh environmental conditions, as it can withstand exposure to moisture, chemicals, and extreme temperatures without compromising its integrity.One leading manufacturer and supplier of galvanized bar grating is {} (), a renowned company with a solid reputation for delivering high-quality products to a diverse range of industries. With years of experience and expertise in the field of industrial flooring solutions, {} () has established itself as a trusted name in the market, providing top-notch galvanized bar grating that meets the highest standards of quality and performance.The company prides itself on its state-of-the-art manufacturing facilities and advanced production techniques, which enable them to produce galvanized bar grating with precision and consistency. Their team of skilled professionals is dedicated to ensuring that every product meets the specific requirements and specifications of their customers, guaranteeing a reliable and efficient solution for industrial flooring needs.In addition to its exceptional durability and corrosion resistance, galvanized bar grating from {} () offers a range of other benefits that make it the preferred choice for industrial applications. Its open grid design allows for easy drainage of liquids, debris, and other materials, minimizing the risk of slips, trips, and falls in the workplace. The non-slip surface of the grating also provides enhanced traction for workers and equipment, further enhancing safety and preventing accidents.Furthermore, the lightweight nature of galvanized bar grating makes it easy to handle and install, reducing labor costs and saving time during the construction or renovation of industrial flooring. Its high strength-to-weight ratio ensures that it can support heavy loads and withstand continuous use without warping or bending, making it a cost-effective and low-maintenance solution for industrial environments.{} () offers a wide variety of galvanized bar grating options, including different mesh sizes, bearing bar spacings, and cross bar spacings to accommodate various load requirements and applications. From industrial walkways and mezzanine floors to drainage covers and catwalks, their galvanized bar grating is customizable to fit the specific needs of each project, providing a versatile and adaptable flooring solution for any industrial setting.As industries continue to demand reliable and long-lasting flooring solutions that can withstand the rigors of daily use, galvanized bar grating has proven to be the superior choice. With its unparalleled durability, corrosion resistance, and safety features, it is the go-to option for industrial flooring, offering a reliable and sustainable solution for businesses across the globe.When it comes to sourcing high-quality galvanized bar grating, {} () is the name to trust. With a commitment to excellence and a track record of delivering top-tier products, they are the leading choice for industrial flooring solutions. Contact {} () today to learn more about their galvanized bar grating options and how they can meet your specific industrial flooring needs.

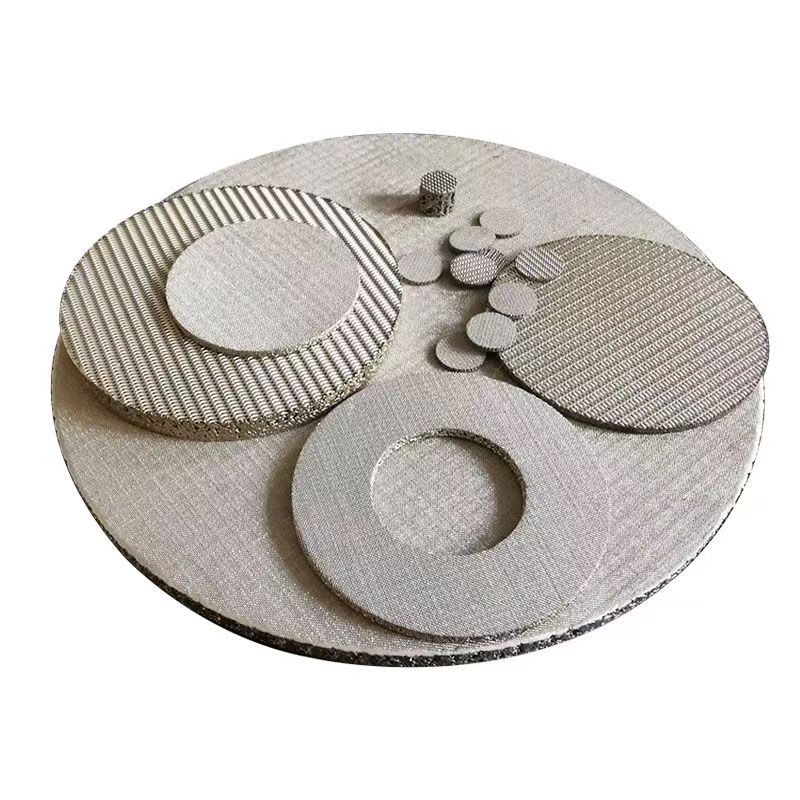

Discover the Versatility of Knitted Wire Mesh for Your Next Project

Title: Innovative Knitted Wire Mesh Revolutionizes Industrial ApplicationsIntroduction:In today's fast-paced industrial landscape, companies are constantly seeking innovative solutions to enhance efficiency and productivity. Knitted Wire Mesh, an increasingly popular material, has emerged as a game-changer in various sectors, providing unmatched versatility and practicality. This news article explores the transformative potential of Knitted Wire Mesh, highlighting its significant impact on industries and showcasing the pioneering efforts of a leading company in its production.Paragraph 1:Knitted Wire Mesh, a versatile and durable material crafted from interlocking loops of metal wire, has revolutionized traditional industrial applications. The mesh's distinct knit structure allows it to be easily manipulated, shaped, and customized, providing an array of benefits across several sectors. Offering an efficient combination of strength, flexibility, and superior airflow, Knitted Wire Mesh outperforms conventional materials in several critical areas.Paragraph 2:One company at the forefront of Knitted Wire Mesh production is {}. This pioneering firm has emerged as a leader in the industry due to its commitment to research and development, advanced manufacturing processes, and unwavering focus on quality. The company's state-of-the-art facilities equipped with specialized machinery allow for the seamless production of Knitted Wire Mesh tailored to specific client requirements.Paragraph 3:The myriad applications of Knitted Wire Mesh span across an extensive range of industries, including automotive, aerospace, pharmaceuticals, filtration, and more. In the automotive sector, the mesh is widely used for exhaust gas recirculation (EGR) systems, catalytic converters, and engine seals, owing to its exceptional heat resistance, durability, and ability to minimize noise and vibration.Paragraph 4:The aerospace sector also benefits significantly from the integration of Knitted Wire Mesh. Aerospace engineers rely on its lightweight yet sturdy composition to enhance insulation, cooling, venting, and noise suppression in aircraft engine compartments. Additionally, the mesh's ability to trap debris and withstand harsh environmental conditions has made it an invaluable component in fuel filtration systems.Paragraph 5:In the pharmaceutical industry, where maintaining sterile environments is crucial, Knitted Wire Mesh finds extensive applications in cleanrooms, isolators, and filtration systems. Its non-contaminating properties, combined with high air-permeability and chemical resistance, make it an ideal component for pharmaceutical processing equipment, ensuring product safety and quality.Paragraph 6:Beyond these specific industries, Knitted Wire Mesh is also utilized in various general filtration applications, effectively eliminating contaminants, separating liquids, and for overall process optimization. The flexibility of the material enables its integration into filters of different sizes and shapes while ensuring consistent and efficient performance.Paragraph 7:The innovative nature of Knitted Wire Mesh has also paved the way for creative applications, such as architectural and interior design. Its malleability and aesthetic appeal have made it a sought-after material for creating decorative elements, partitions, and intricate structures. Such applications showcase the mesh's versatility, while its durability ensures long-lasting results.Conclusion: Knitted Wire Mesh has become a critical component in various industrial sectors due to its exceptional characteristics and numerous benefits. Through the pioneering efforts of companies like {}, this innovative material continues to revolutionize industries, transcending traditional limitations and setting new benchmarks for efficiency, customization, and performance. As the demand for versatile solutions increases, Knitted Wire Mesh remains an indispensable tool, propelling industries forward into the future of manufacturing and design.